Blackening Treatment Round Self Clinching Nut

Send Inquiry

To make blackening treatment round self clinching nut-Blackening treatment work better and last longer, they get different surface coatings. Here’s the lowdown on common ones:

Steel nuts often get zinc plating,you can get clear, yellow, or black chromate finishes. That’s a cost-friendly way to protect them from rust. Then there’s Geomet™, which is a zinc flake coating. It’s really good at fighting corrosion and chemicals, and it meets a lot of automotive standards.

Stainless steel nuts usually go through a passivation process. That just helps boost the corrosion resistance they already have. For aluminum nuts, they might get anodized (which can be clear or colored) or get a chem-film (that’s a chromate conversion coating).

All these finishes do the same job: they shield the nuts from moisture, chemicals, and wear and tear. That’s key if you want them to last a long time.

Industry standards and parameters:

Blackening treatment round self clinching nut follow industry rules, usually based on DIN 7337 or something similar. This makes sure they can replace each other no matter who makes them.

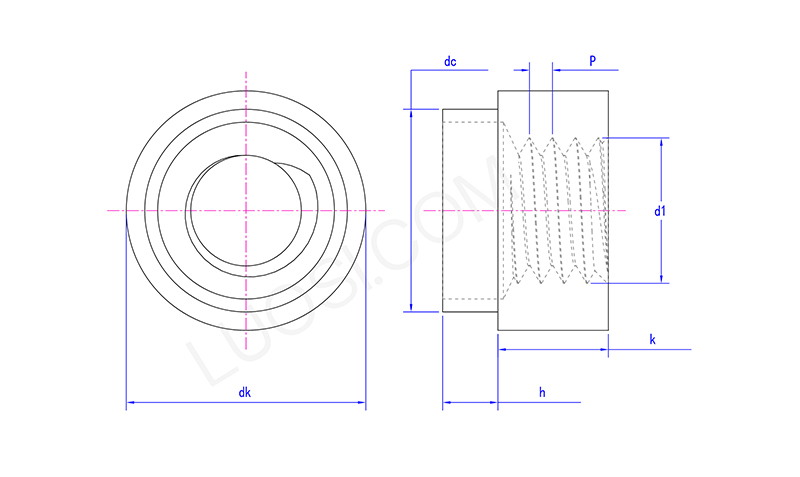

You measure them by different things: the thread size (like M4, M5, and so on), how wide the body is, how wide the flange is, and how thick the material can be when you use them. Standard thread sizes usually go from M3 to M12.

The big difference is that after you install these nuts, the flange (the part that spreads out) is much wider than the body was before. That’s what makes them so good at not pulling through materials.

When you pick a nut, you’ve got to know the exact measurements. You need to match the nut to the size of the hole and how thick the material is. If you don’t, it won’t work right.

| Mon | M3-1.5 | M3-2 | M4-1.2 | M4-1.5 | M4-2 | M5-2 | M5-3 | M6-2 | M6-3 | M8-2 | M8-3 |

| P | 0.5 | 0.5 | 0.7 | 0.7 | 0.7 | 0.8 | 0.8 | 1 | 1 | 1.25 | 1.25 |

| dk max | 7.25 | 7.25 | 8.25 | 8.25 | 8.25 | 10.25 | 10.25 | 11.25 | 11.25 | 13.25 | 13.25 |

| dk min | 6.75 | 6.75 | 7.75 | 7.75 | 7.75 | 9.75 | 9.75 | 10.75 | 10.75 | 12.75 | 12.75 |

| dc max | 4.98 | 4.98 | 5.98 | 5.98 | 5.98 | 7.95 | 7.95 | 8.98 | 8.98 | 10.98 | 10.98 |

| k max | 3.25 | 3.25 | 4.25 | 4.25 | 4.25 | 5.25 | 5.25 | 6.25 | 6.25 | 6.25 | 6.25 |

| k min | 2.75 | 2.75 | 3.75 | 3.75 | 3.75 | 4.75 | 4.75 | 5.75 |

5.75 |

5.75 |

5.75 |

| h max | 1.6 | 2.1 | 1.3 | 1.6 | 2.1 | 2.1 | 3.1 | 2.1 | 3.1 | 2.1 | 3.1 |

| h min | 1.4 | 1.9 | 1.1 | 1.4 | 1.9 | 1.9 | 2.9 | 1.9 | 2.9 | 1.9 | 2.9 |

| d1 | M3 | M3 | M4 | M4 | M4 | M5 | M5 | M6 | M6 | M8 | M8 |

What tools are needed for installation?

To install a blackening treatment round self clinching nut, you need a special setting tool called a mandrel. This tool threads into the nut's inner threads. When you pull or apply force to the tool, it makes the nut expand outward, deforming it so it grips the tube wall tightly.

There are manual setting tools, but for most cases,especially in factory setups,pneumatic or hydraulic tools are better. They give consistent force, which makes sure the nut is installed properly every time. That consistency is key for reliable performance, especially when you're doing lots of installations.