Black Oxide Round Head Bolt

Send Inquiry

The installation process for black oxide round head bolts is more complicated than for regular bolts. The square neck needs to be aligned with the square hole in the connected part, then the bolt is inserted and the nut is tightened. The installation process is a little more complicated and requires ensuring that the square neck fits the square hole accurately to achieve a good anti-rotation effect.

Features

The characteristic of the black oxide round head bolts is that the head is made into a semi-spherical shape, and a square neck is made under the head. On the connected parts connected by this kind of bolt, a square hole must be made correspondingly.

Black oxide round head bolts is mostly used on trucks, barges, ironwood looms, and other wooden structural parts. Due to the large bearing surface of the head, it is not easy to sink into the wooden connected parts.

Installation

Preparation:

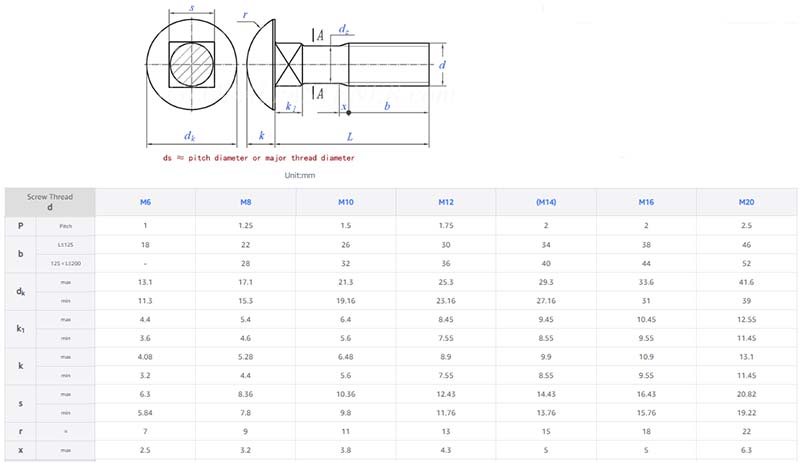

Confirm that the specifications and dimensions of black oxide round head bolts match the requirements of the connected parts,and prepare the required installation tools, such as wrenches. At the same time, clean the mounting holes and surfaces of the connected parts to ensure that the mounting surface is flat and clean.

Insert the bolts:

Pass the screw part of black oxide round head bolts through the light holes of the connected parts,so that the square neck part is aligned and embedded in the corresponding square holes on the connected parts, make sure that the square neck and the square holes fit tightly, and that the head of the bolts is close to the surface of the connected parts.

Screw on the nut: Screw the nut onto the threaded part of the bolt,and initially tighten it by hand to bring the nut into contact with the washer or the surface of the connected part.When screwing on the nut,take care to ensure that the threads of the nut engage correctly with the threads of the bolt to avoid any thread misalignment.

Tightening with tools:

Using a suitable wrench to further tighten the nut in accordance with the specified torque value or tightening force requirements.Keeping the wrench perpendicular to the nut and exert uniform force during tightening to avoid deformation or fracture caused by uneven force on the black oxide round head bolt.For some important connection parts,it may be necessary to using a torque wrench to precisely control the tightening torque to ensure the reliability of the connection.

Checking the installation:

After the installation is completed,checking the tightening of the bolts and nuts to make sure that the bolt heads and nuts fit closely with the surface of the connected parts without loosening.

Why choose us

(1)Black oxide round head bolts with stable and traceable raw material supplying lines

(2)10 years manufacturing and exporting experience

(3)Controllable delivery time

(4)Flexible payment term

(5)Multilingual service: English/Russian/Spanish and so on.