Weld Hexagon Nuts With Flanges

Send Inquiry

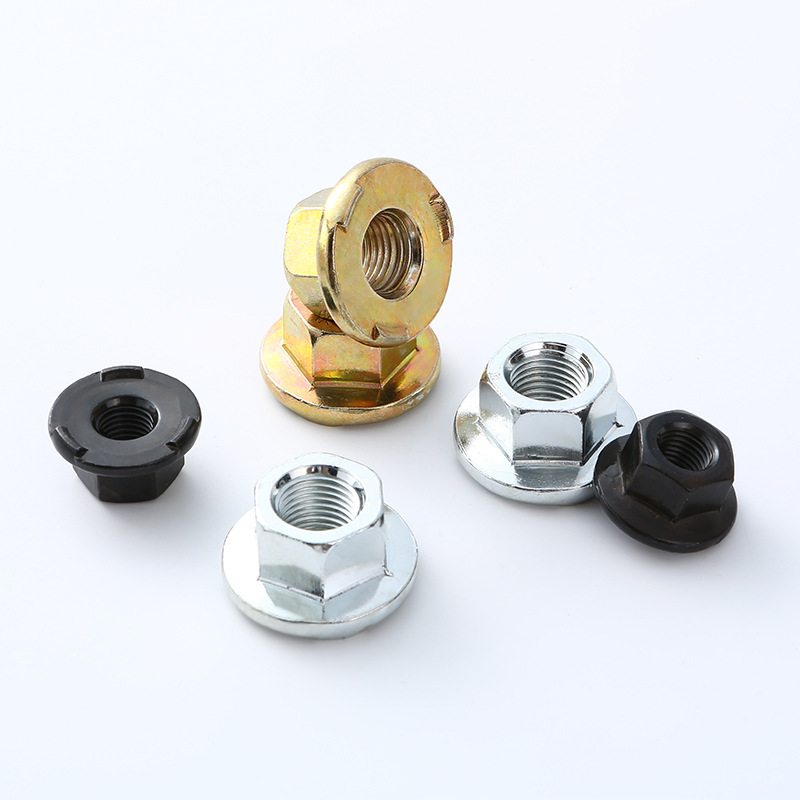

Weld hexagon nuts with flanges are special fasteners. They have a regular hexagonal head that you can use a wrench on, plus a wide, circular base (the flange) that’s part of the nut. This flange means you don’t need a separate washer. These nuts are mainly made to be attached permanently. They have a little raised part for welding or a specific base shape that lets them weld securely right onto structures, pipes, or equipment surfaces. That way, you get a strong, fixed threaded spot.

Advantage:

The main good thing about Weld hexagon nuts with flanges is that they’re all one piece. Flanges spread the clamping force over a larger area, and since sealing effectiveness is directly proportional to force uniformity, there is less stress on the surface they are attached to. This also makes them less likely to loosen due to vibration.This built-in stability, along with being welded on permanently, makes these nuts really reliable. They work well in high-stress or important uses where keeping the fastener secure is super important.

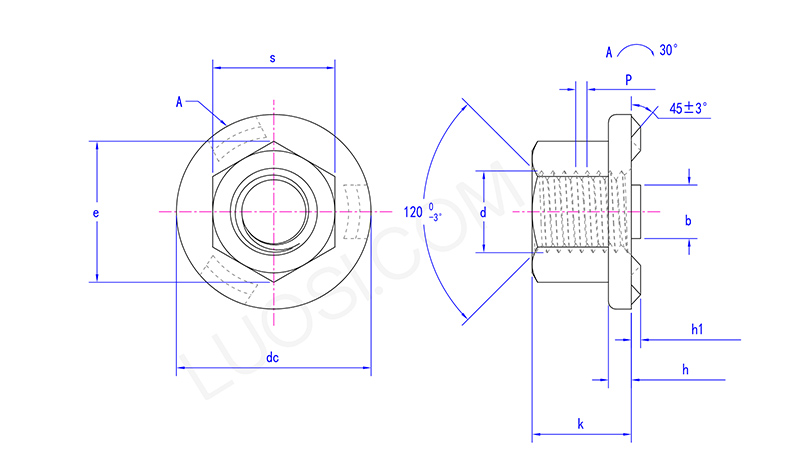

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| h1 max | 0.9 | 0.9 | 1.1 | 1.3 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.7 | 0.7 | 0.9 | 1.1 | 1.1 | 1.1 | 11 |

| dc max | 15.5 | 18.5 | 22.5 | 26.5 | 30.5 | 33.5 | 36.5 |

| dc min | 14.5 | 17.5 | 21.5 | 25.5 | 29.5 | 32.5 | 35.5 |

| e min | 8.2 | 10.6 | 13.6 | 16.9 | 19.4 | 22.4 | 25 |

| h max | 1.95 | 2.25 | 2.75 | 3.25 | 3.25 | 4.25 | 4.25 |

| h min | 1.45 | 1.75 | 2.25 | 2.75 | 2.75 | 3.75 | 3.75 |

| b max | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 8.1 | 8.1 |

| b min | 3.9 | 4.9 | 5.9 | 6.9 | 7.9 | 7.9 | 7.9 |

| k max | 4.7 | 6.64 | 9.64 | 12.57 | 14.57 | 16.16 | 18.66 |

| k min | 5 | 7 | 10 | 13 | 15 | 17 | 19.5 |

| s max | 8 | 10 | 13 | 16 | 18 | 21 | 24 |

| s min | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 |

Welding method:

Weld hexagon nuts with flanges are mainly made to be used with projection welding (that’s a type of resistance welding) to attach them to fasteners or parts. They can also work for arc welding (like MIG or TIG) in some cases. But you need to use the right method—otherwise, you might damage the flange or the threads, and that would mess up the nut’s integrity.