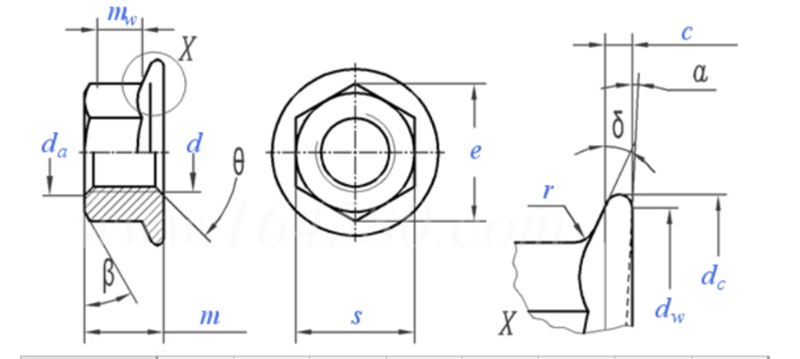

Universal Modified Flange Nut

Send Inquiry

Using this Universal Modified Flange Nut is similar to regular nuts but with a key difference—the built-in flange. First, confirm it matches your bolt’s thread size (metric or imperial). The flange side (the wider, flat part) should face the surface you’re securing. This replaces the need for a washer, which saves a step.

Line up the nut with the bolt’s end and twist it clockwise by hand to start. Then use a wrench to tighten it—don’t over-tighten, as it might damage the surface or strip the threads. It works well for parts that need stable fastening, like automotive components, furniture frames, or small machinery. The flange’s serrations (if present) help prevent loosening from vibration. Universal Modified Flange Nut is ideal for places where adding a separate washer is inconvenient or space is limited.

Product Packaging

We package this nut to keep it safe during shipping and easy to sort. For small orders—like 50 to 200 pieces—they go into clear plastic bags. Each bag has a simple label with size, quantity, and material info. You can check the contents without opening the bag, which saves time when you’re organizing parts.

Bulk orders—1000 pieces or more—use thick cardboard boxes. We put small plastic dividers or separate inner bags inside to stop the nuts from scratching each other’s flange surfaces. All outer boxes have a thin moisture-proof layer to prevent rust on metal nuts. If you need custom packaging for retail sales, just mention it when placing your order. Universal Modified Flange Nut follows these basic packaging rules, no extra frills, just to ensure it arrives in usable condition.

Q&A Session

Does it really not need a washer? Can the flange replace a washer completely?

A: Yes, the flange is designed to replace a washer. The wide, flat flange distributes pressure evenly on the surface, just like a regular washer. It also prevents the nut from digging into soft materials like wood or thin metal. For most common fastening jobs—like furniture assembly or light machinery parts—it works perfectly without an extra washer. Only in extreme cases, like high-pressure industrial equipment, you might need an additional washer, but that’s rare for daily use scenarios.

| d | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | M20 | ||

| P | pitch | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | |

| c | Minimum value | 1.0 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3.0 | |

| da | Maximum value | 5.75 | 6.75 | 8.75 | 10.80 | 13.00 | 15.10 | 17.30 | 21.60 | |

| Minimum value | 5.00 | 6.00 | 8.00 | 10.00 | 12.00 | 14.00 | 16.00 | 20.00 | ||

| dc | Maximum value | 11.8 | 14.2 | 17.9 | 21.8 | 26 | 29.9 | 34.5 | 42.8 | |

| dw | Minimum value | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |

| e | Minimum value | 8.79 | 11.05 | 14.38 | 16.64 | 20.03 | 23.36 | 26.75 | 32.95 | |

| m | Maximum value | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Minimum value | 4.7 | 5.7 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 18.7 | ||

| mw | Minimum value | 2.5 | 3.1 | 4.6 | 5.6 | 6.8 | 7.7 | 8.9 | 10.7 | |

| s | Maximum value | 8 | 10 | 13 | 15 | 18 | 21 | 24 | 30 | |

| Minimum value | 7.78 | 9.78 | 12.73 | 14.73 | 17.73 | 20.67 | 23.67 | 29.16 | ||

| r | Maximum value | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1.0 | 1.2 | |

| 1000 pieces (steel)=kg | 2.11 | 3.81 | 7.79 | 12.82 | 22.01 | 34.32 | 51.21 | 97.81 | ||