High Quality Flange Nut

Send Inquiry

This High Quality Flange Nut uses common metals that fit most fastening needs. The most widely used one is carbon steel. It’s affordable and works for regular indoor jobs, like furniture assembly or small tool fixtures. It usually has basic surface treatment to prevent mild rust, nothing extra.

For scenarios needing rust resistance—like outdoor fixtures or damp environments—stainless steel is a better pick. It holds up well against water and humidity. Some industrial uses opt for alloy steel; it’s stronger, fitting for machinery parts that bear more load. All materials meet basic industry standards, no special quality claims. High Quality Flange Nut’s material options are simple, so you just choose based on where and how you’ll use it.

Product surface treatment

The surface treatment is mainly for preventing rust and protecting the flange part. The most common type is zinc plating. It’s cost-effective and fits regular indoor uses, like furniture or small tool fixtures. It forms a thin protective layer that stops mild rust without affecting the nut’s fit with bolts.

For outdoor or damp environments, hot-dip galvanizing is a better choice. It’s a thicker coat, so it holds up well against rain and humidity. Some industrial-grade ones get black oxide treatment; it adds a bit more wear resistance, no fancy effects. These treatments don’t damage the flange’s flat surface or serrations (if any). High Quality Flange Nut gets these basic treatments based on usage needs, just to keep the metal in usable condition for daily or industrial use.

Q&A Session

Q: Will the serrated flange wear out the surface of my products when tightening?

A:It depends on the surface material. For hard surfaces like steel or aluminum, the serrations won’t cause obvious wear. For soft materials like plastic or painted wood, you might see slight marks. If you’re worried about this, you can choose the non-serrated flange type we offer. The serrations are mainly for anti-loosening, so if vibration isn’t a big issue, non-serrated ones are safer for soft surfaces. We can also suggest the right type based on your product’s surface material if you tell us details.

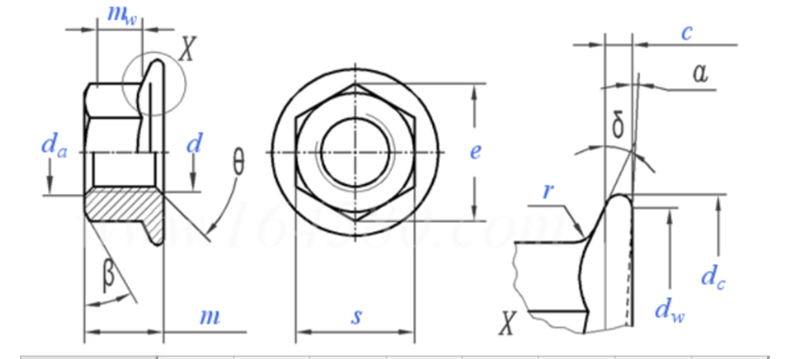

| d | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | M20 | ||

| P | pitch | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | |

| c | Minimum value | 1.0 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3.0 | |

| da | Maximum value | 5.75 | 6.75 | 8.75 | 10.80 | 13.00 | 15.10 | 17.30 | 21.60 | |

| Minimum value | 5.00 | 6.00 | 8.00 | 10.00 | 12.00 | 14.00 | 16.00 | 20.00 | ||

| dc | Maximum value | 11.8 | 14.2 | 17.9 | 21.8 | 26 | 29.9 | 34.5 | 42.8 | |

| dw | Minimum value | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |

| e | Minimum value | 8.79 | 11.05 | 14.38 | 16.64 | 20.03 | 23.36 | 26.75 | 32.95 | |

| m | Maximum value | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Minimum value | 4.7 | 5.7 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 18.7 | ||

| mw | Minimum value | 2.5 | 3.1 | 4.6 | 5.6 | 6.8 | 7.7 | 8.9 | 10.7 | |

| s | Maximum value | 8 | 10 | 13 | 15 | 18 | 21 | 24 | 30 | |

| Minimum value | 7.78 | 9.78 | 12.73 | 14.73 | 17.73 | 20.67 | 23.67 | 29.16 | ||

| r | Maximum value | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1.0 | 1.2 | |

| 1000 pieces (steel)=kg | 2.11 | 3.81 | 7.79 | 12.82 | 22.01 | 34.32 | 51.21 | 97.81 | ||