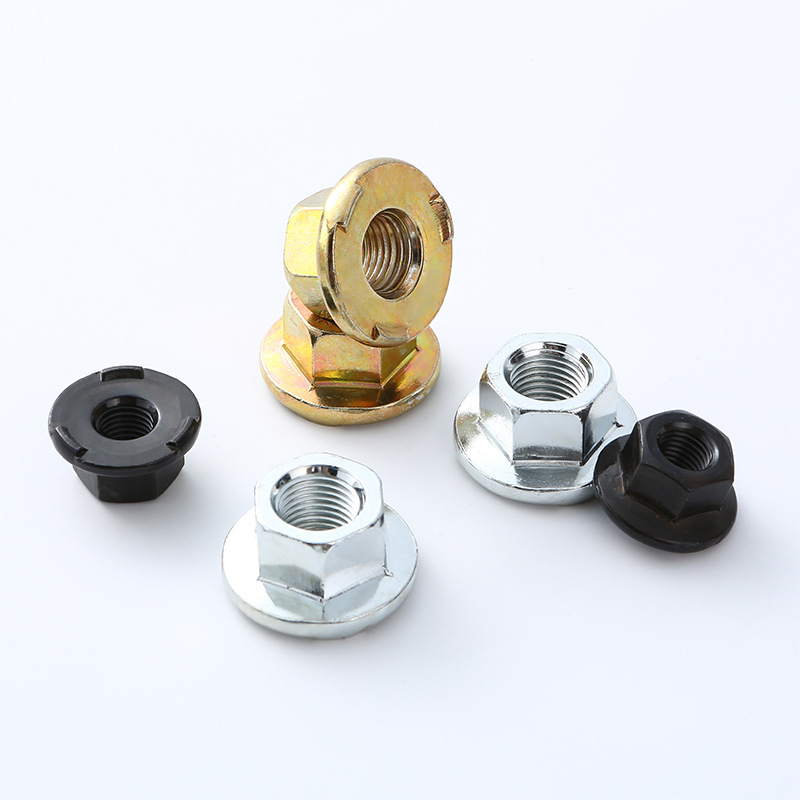

Vibration Resistant Welding Flange Nut

Send Inquiry

The aerospace industry relies on Vibration Resistant Welding Flange Nuts because they’re made to very exact specs and have to meet really tight safety rules. You’ll find these in plane frames, engine parts, and inside the cabin—they’re light but still strong, which makes them a good fit for planes.

Before being officially approved for use, these materials must first pass several rigorous tests. Whether it's their ability to withstand high and low temperatures, withstand repeated use, or meet safety standards, each test must be conducted according to the high standards of the aviation industry to ensure that they are reliable and fully meet the requirements after being installed on the aircraft. They have to handle wear, resist rust, and perform under seriously hot or cold conditions. Their flanged design means you don’t need extra washers, which cuts down on weight and makes assembly simpler.

There are also strict quality checks for every single one, so they work perfectly in those critical aerospace jobs. Basically, when you’re dealing with aircraft—where safety and performance can’t be compromised—these nuts are a reliable choice that checks all the boxes.

Product Advantages

Vibration Resistant Welding Flange Nuts are a good fit for marine jobs—you know, where there's lots of saltwater and moisture, so they’ve gotta handle rust well. these nuts are usually stainless steel or galvanized—basically coated to resist rust better.

You’ll spot them on ships, oil rigs, or underwater, holding together pipes, hull parts, and deck fittings. They seal up tight to block water, which helps avoid leaks and keeps things firmly in place.

These nuts are made tough enough to handle salty places, and you won’t have to spend much time maintaining them. So if your work involves seawater (where regular nuts rust away super fast), these are the ones you can count on—they’ll last way longer.

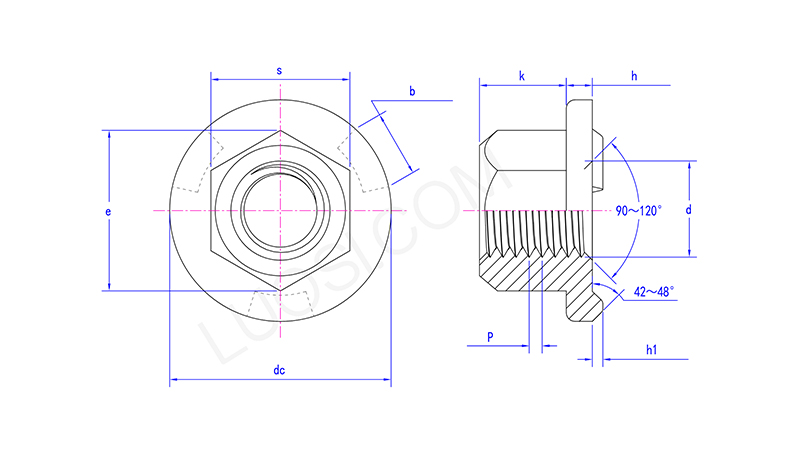

| Mon | M8 | M10 | M12 | M14 |

| P | 1.25 | 1.5 | 1.75 | 2 |

| h1 max | 1.1 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.9 | 1.1 | 1.1 | 1.1 |

| dc max | 22.5 | 26.5 | 30.5 | 33.5 |

| dc min | 21.5 | 25.5 | 29.5 | 32.5 |

| e min | 13.6 | 16.9 | 19.4 | 22.4 |

| h max | 2.75 | 3.25 | 3.25 | 4.25 |

| h min | 2.25 | 2.75 | 2.75 | 3.75 |

| b max | 6.1 | 7.1 | 8.1 | 8.1 |

| b min | 5.9 | 6.9 | 7.9 | 7.9 |

| k min | 9.64 | 12.57 | 14.57 | 16.16 |

| k max | 10 | 13 | 15 | 17 |

| s max | 13 | 16 | 18 | 21 |

| s min | 12.73 | 15.73 | 17.73 | 20.67 |

Q: Are your Vibration Resistant Welding Flange Nuts certified to international standards?

A:Yep, our nuts are produced under international certifications like ISO 9001 and DIN 929. That means every Vibration Resistant Welding Flange Nut we make is checked to match quality, size, and performance specs—so you know it’s reliable and built to last.