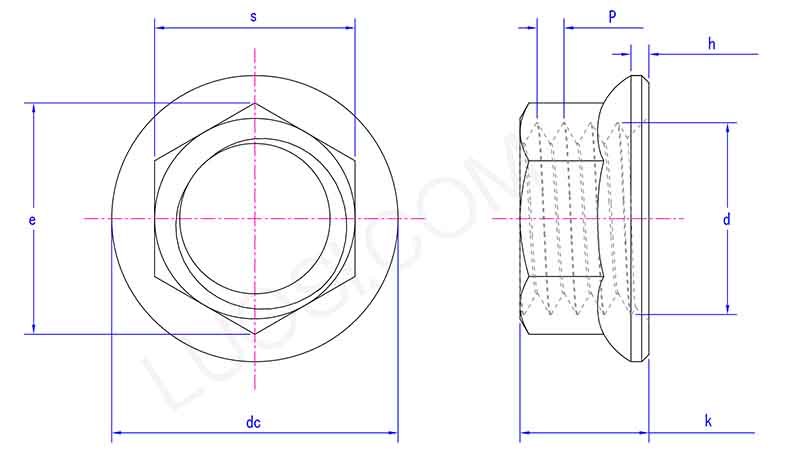

High Precision Hexagon Nuts With Flange

Send Inquiry

High precision hexagon nuts with flange are mostly made from medium carbon steel or alloy steel.These nuts undergo a high-temperature heat treatment process to achieve high strength grades such as 8, 10, and 12 according to ISO or SAE standards.Through special heat treatment processes such as quenching and tempering, its tensile strength, yield strength and hardness are far superior to ordinary nuts.After this heat treatment process, the nut can withstand high pressure and can be used stably in harsh environments.So they work reliably for a long time.

Application Areas

High precision hexagon nuts with flange are used a lot in places where the connection has to stay strong even under high stress and vibration,you can’t ignore that. Main areas they’re used in are putting together heavy machines, building structural steel (like bridges and buildings), tough car parts (suspensions, engines, chassis), important aerospace parts, railway setups, and high-pressure pipeline connections. They resist vibration and can spread out strong clamping loads, so they’re really needed anywhere safety and reliability are really important. That way, the connection doesn’t break in a bad way.

Material grades and coatings

Q:What material grades and coatings are available for corrosion protection?

A:Our high precision hexagon nuts with flange are mainly made from medium carbon steel, alloy steel, or boron steel. They’re heated and treated to reach Property Classes 8, 10, or 12. To resist rust, we offer different coatings: standard zinc plating (clear or yellow), hot-dip galvanizing (which gives thicker protection), Geomet® (that’s a Zn/Al flake coating), and Dacromet®. Which one you pick depends on how much rust protection you need,like how many hours of salt spray they can handle,and the environment they’ll be in.

|

Mon |

#4 |

#6 |

#8 |

#10 |

1/4 | 5/16 | 3/8 |

|

P |

40 | 32 | 32 | 32 | 28 | 24 | 24 |

|

dc max |

0.206 | 0.244 | 0.29 | 0.33 | 0.42 | 0.52 | 0.62 |

|

e min |

0.171 | 0.207 | 0.244 | 0.277 | 0.347 | 0.419 | 0.491 |

|

k max |

0.125 | 0.141 | 0.188 | 0.188 | 0.219 | 0.268 | 0.282 |

|

k min |

0.103 | 0.115 | 0.125 | 0.154 | 0.204 | 0.251 | 0.267 |

|

h min |

0.01 | 0.01 | 0.015 | 0.015 | 0.019 | 0.023 | 0.03 |

|

s max |

0.158 | 0.19 | 0.221 | 0.252 | 0.316 | 0.378 | 0.44 |

|

s min |

0.15 | 0.181 | 0.213 | 0.243 | 0.304 | 0.367 | 0.43 |