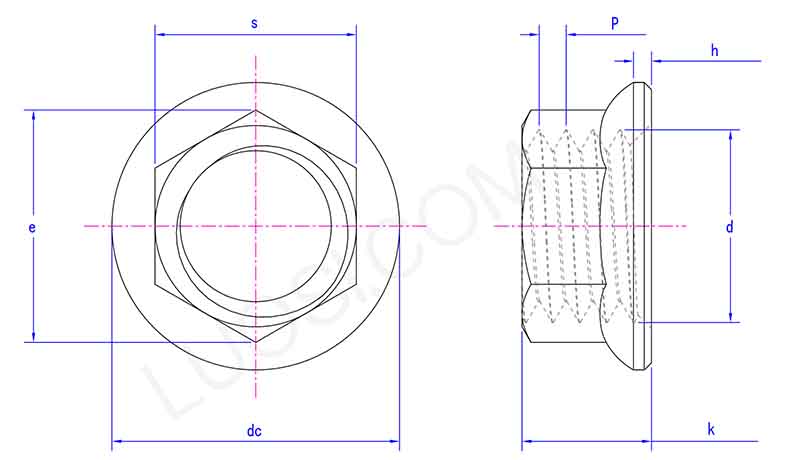

Hexagon Flange Nuts For Industrial Buildings

Send Inquiry

The hexagon flange nuts for industrial buildings are strong because they use specific material grades that follow global standards. Common metric grades are 8, 10, and 12,this is under ISO 898-2. For imperial, there’s 5, 8, and 9, based on SAE J995 and ASTM A563. Grades like 8, ISO 10, and higher are the strongest ones. These grades guarantee a minimum tensile strength,like 1040 MPa for ISO 10,and a minimum proof load.

They’re usually made from carbon steel or alloy steel, like 35CrMo, and then heat-treated. That way, they consistently meet these strict mechanical needs.

Regular inspection and replacement

Even though hexagon flange nuts for industrial buildings are built to last and work reliably, you should probably check them now and then if they’re used in key spots. Just take a look,keep an eye out for too much rust, damage to the part of the flange that touches the surface, or threads getting bent or messed up.

Make sure the nut stays tight enough, especially after they have been in use for a little while,they might settle a bit at first. You might need to retighten them, depending on what the job needs.

Don’t put lube on the flange face unless they say to. That stuff can change how much friction there is and mess with how tight the clamp is. If a nut is really worn out or rusted bad, swap it out right away.

Mon

#4

#6

#8

#10

1/4

5/16

3/8

P

40

32

32

32

28

24

24

dc max

0.206

0.244

0.29

0.33

0.42

0.52

0.62

e min

0.171

0.207

0.244

0.277

0.347

0.419

0.491

k max

0.125

0.141

0.188

0.188

0.219

0.268

0.282

k min

0.103

0.115

0.125

0.154

0.204

0.251

0.267

h min

0.01

0.01

0.015

0.015

0.019

0.023

0.03

s max

0.158

0.19

0.221

0.252

0.316

0.378

0.44

s min

0.15

0.181

0.213

0.243

0.304

0.367

0.43

Hexagonal flange nuts (lock nuts) with pre-torque for critical vibration applications

We have lock nut versions of our hexagon flange nuts for industrial buildings’these are the ones that stay tight on their own. They have a non-metal piece, usually nylon, stuck into the top part of the nut’s threads. When you tighten the nut, this piece rubs against the bolt’s threads. That creates a kind of "staying torque" that stops it from coming loose, even with vibration, shocks, or temperature changes. And they still keep the high strength and load-spreading benefits of the flange design.