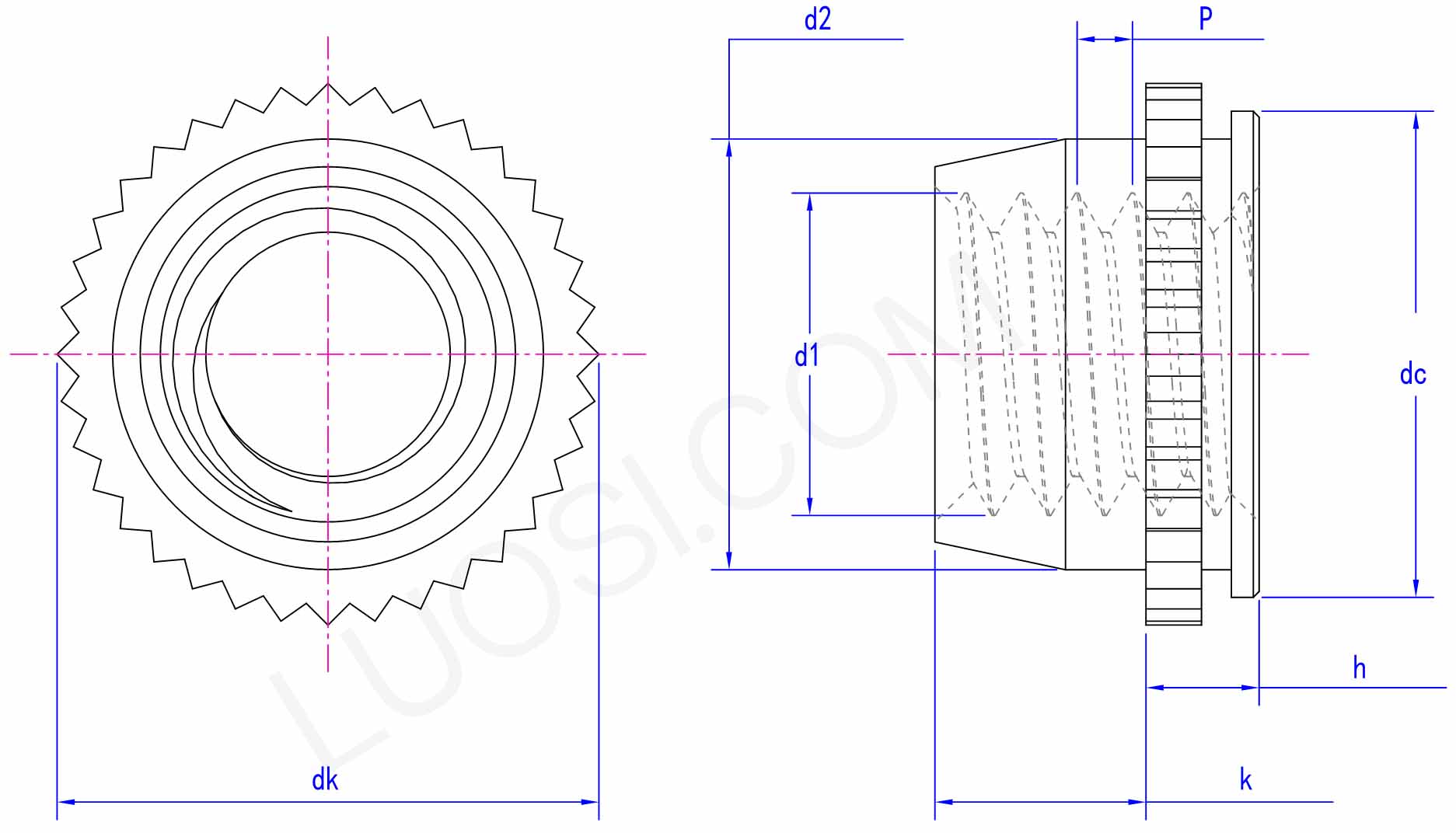

UN miniature riveted nut

Send Inquiry

UN miniature riveted nuts are usually made from tough aluminum alloys, A2 or A4 stainless steel, or sometimes carbon steel. They pick these materials because they just work well. The aluminum kinds are strong but light, and they hold up against rust pretty well in lots of places. The stainless steel versions fight off corrosion better and give you more strength for heavier-duty jobs.

The way these metals naturally behave makes sure the self-locking collar bends right when you put it in and keeps holding tight.

Product parameters

| Mon | 440 | 632 | 832 | 032 | 0420 | 0428 |

| P | 40 | 32 | 32 | 32 | 20 | 28 |

| d1 | #4 | #6 | #8 | #10 | 1/4 | 1/4 |

| d2 max | 0.145 | 0.18 | 0.215 | 0.245 | 0.318 | 0.318 |

| dc max | 0.171 | 0.212 | 0.289 | 0.289 | 0.343 | 0.343 |

| dc min | 0.166 | 0.207 | 0.284 | 0.284 | 0.338 | 0.338 |

| dk max | 0.197 | 0.249 | 0.327 | 0.327 | 0.389 | 0.389 |

| dk min | 0.187 | 0.239 | 0.317 | 0.317 | 0.379 | 0.379 |

| h max | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| k max | 0.08 | 0.09 | 0.105 | 0.125 | 0.135 |

0.135 |

| k min | 0.065 | 0.075 | 0.09 | 0.11 | 0.12 | 0.12 |

Features

UN miniature rivet nuts are commonly used for fastening in confined spaces, such as electronic housings, small instruments, medical devices, aircraft components (especially avionics), telecommunications equipment, precision optical mounts, and compact robotics. These nuts can be used on thin metal sheets where backside access is not possible, acting as anti-vibration thread anchors on panels.

What materials and coatings are used for corrosion resistance?

UN miniature riveted nuts are typically manufactured from steel, commonly Grade 8 steel or stainless steel grades such as 304/316, though aluminium variants are also available. To prevent corrosion, various surface treatments may be selected: zinc plating (clear or yellow), nickel plating, or anodising for aluminium nuts. When selecting materials and surface treatments, matching must be based on the operating environment and strength requirements. This ensures the nuts remain durable and perform reliably over time.