Un Insert Nut

Send Inquiry

The UN insert nut is a heat-treated stainless steel nut.They stop threads from stripping in soft materials, can pass salt-spray tests lasting over 10,000 hours (ASTM B117), and work in temps from -200°C to 800°C. Compared to welded parts, they’re lighter, which cuts down on the weight of the whole system.

They also make assembly and disassembly faster, so you save on labor costs. And when it comes to the environment, these nuts are 100% recyclable. That fits well with sustainable manufacturing goals in a bunch of industries.

Detection

Every batch of these heat-treated stainless steel UN insert nuts goes through strict testing. They check Rockwell hardness, do torque-to-failure tests, and use metallography to make sure the heat treatment is even. They have certifications like RoHS, REACH, and ISO 9001. Each nut gets a laser-marked lot code so you can trace where it came from.

By working with certified suppliers, these nuts meet military specs (MIL-SPEC) or DIN standards for important projects. That way, you can be sure they’ll hold up,no need to worry about quality.

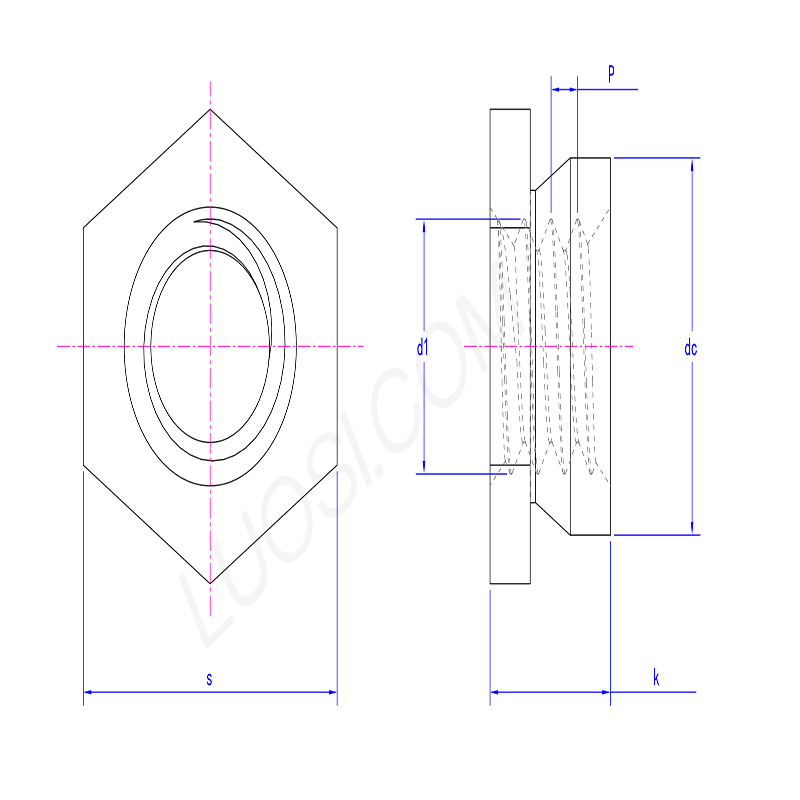

Product parameters

| Mon | 256-1 | 256-2 | 440-1 | 440-2 | 632-1 | 632-2 | 832-1 | 832-2 | 032-1 | 032-2 | 0420-3 |

| P | 56 | 56 | 40 | 40 | 32 | 32 | 32 | 32 | 32 | 32 | 20 |

| d1 | #2 | #2 | #4 | #4 | #6 | #6 | #8 | #8 | #$10 | #10 | 1/4 |

| dc max | 0.171 | 0.171 | 0.171 | 0.171 | 0.212 | 0.212 | 0.289 | 0.289 | 0.311 | 0.311 | 0.343 |

| k max | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.12 |

| s | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | 0.312 | 0.312 | 0.343 | 0.343 | 0.375 |

Corrosion resistance and service life in harsh environments

Using 316L stainless steel with heat treatment makes these UN insert nuts really good at resisting corrosion. They hold up way better against moisture, lots of chemicals, and salt spray compared to untreated carbon steel or lower-grade stainless inserts. That means in tough environments, these nuts stay reliable for a long time and need less maintenance.