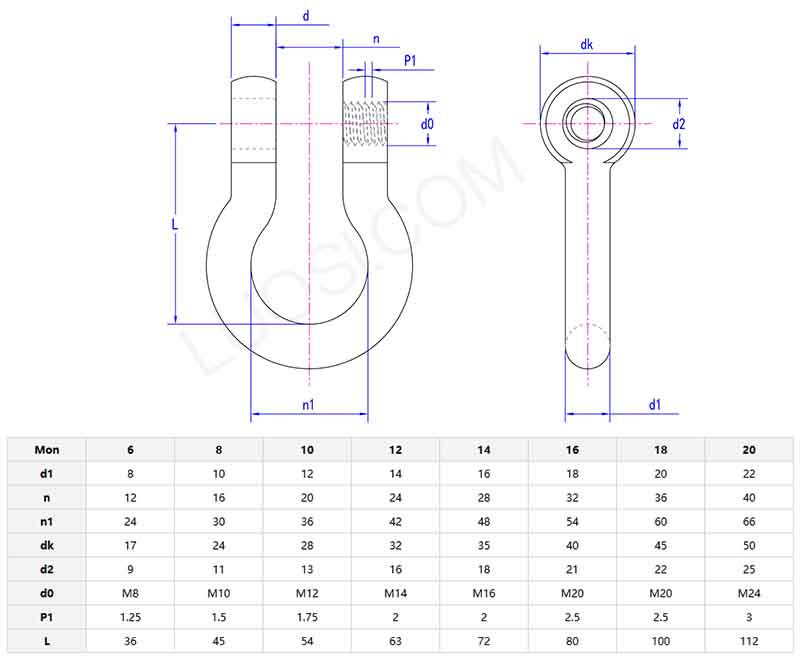

Type BD Shackles

Send Inquiry

Type BD shackles are made from high-tensile alloy steel. The material doesn’t get brittle when it takes sudden, heavy loads, and its fine-grained makeup helps it last longer under repeated stress. Xiaoguo® also heat-treat the alloy to make it harder,reaching a hardness of HRC 40-45 to resist scrapes and surface damage.

Because of all this, the shackle stays strong even after being put under high stress many times, so you can count on it lasting a long time.

Application

Type BD shackles are often used where loads need to be managed safely, such as mooring vessels offshore, installing rigging in theatres or assembling heavy machinery. Their rust-resistant coating makes them ideal for offshore operations, such as transporting cargo between ship and shore or performing underwater salvage operations.

In the construction industry, BD shackles are used to attach crane hooks to steel beams or precast concrete elements.Outdoor enthusiasts who do off-road vehicle recovery also depend on these shackles because they can handle sudden shocks. Whether it’s in industrial manufacturing or renewable energy projects like installing wind turbines, these shackles provide a reliable connection in systems that carry heavy loads.

Materials

Q: What materials are used in type BD shackles, and how do they resist corrosion?

A:BD type shackles are made from carbon steel that’s treated with heat, so they’re pretty tough and don’t wear out easily. To stop rust, they get a zinc coating applied by hot-dipping,this helps them survive salty water or damp areas without corroding.