Plain Axial Snap Ring

Send Inquiry

When installing plain axial snap ring, use special circlip pliers to keep them from bending out of shape. Make sure the groove where they go is clean, free of burrs, and lined up with the ring's open ends. Check them often for wear, rust, or small cracks, especially in parts that get used a lot or vibrate a lot.

Put a little light oil on them during assembly to reduce friction. Don’t stretch or squeeze the ring too much—only as much as needed to fit it in place. If the ring stays bent or misshapen after you install it, replace it with a new one.

Store these rings in dry places where the temperature doesn’t change much. This keeps them from getting damaged before you use them and helps them stay strong and work right.

Product details:

Plain axial snap ring save cash because they use fewer parts and less work to assemble stuff. Unlike glued or welded bits, you can pop them off and reuse them without wrecking anything. Buying them in bulk and using standard sizes also saves storage space. They’re tough, so you replace them less, which helps keep pricey machines running longer. Unlike threaded parts, you skip lock washers or thread glue with these rings—so they cut daily costs in fields like car factories or renewable energy gear.

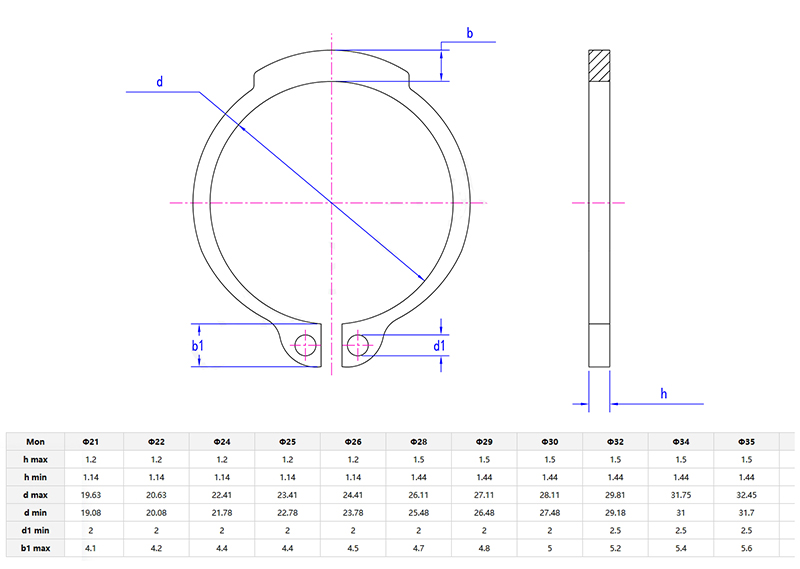

Product parameters

FAQ:

Q: What temperature ranges can plain axial snap ring withstand?

A: Work in different temps based on their material. Carbon steel ones usually handle -30°C to 120°C. Stainless steel (like AISI 316) works in way colder or hotter spots, from -200°C up to 300°C. For crazy heat (like jet engines), they use metals like Inconel® that don’t quit until 700°C.

If you push them way hotter or colder than they’re rated, they might lose their grip or snap easier. For high-heat jobs (think rockets), use rings that are heat-treated during production and coated (zinc-nickel, for example). Always check with your supplier about temp limits—using the wrong ones can wreck your whole setup.