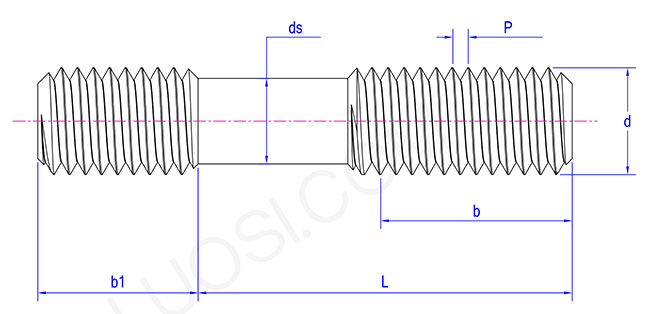

Type B Double End Stud

Send Inquiry

Type B double end stud is a metal rod with threads at both ends. The lengths of the threads at both ends are different, which can adapt to connection materials of different thicknesses. The diameter of the middle smooth rod part is the same as that of the thread, making it very flexible to use.

Applications and parameters

Type B double end studs are used in the machinery manufacturing industry. When assembling the machine tool, use it to fix the worktable and the bed. Screw the short end into the threaded hole of the bed, and after the long end passes through the worktable, tighten it with a nut. It can withstand the vibration during processing.

When repairing the motor, type B studs are used to replace the end cover. The short end is fixed to the motor housing, and the long end is connected to the end cover to ensure that the end cover does not loosen when the motor is running and protect the internal parts. They can withstand the vibration and weight during the operation of the equipment, prevent the equipment from shifting, and ensure production safety.

This B double end studs solved the alignment problem. First, fully screw the studs into one component, then adjust the position, and finally tighten the nut at the free end. This is crucial for leveling the mechanical base on uneven shims. They can evenly distribute the load. The uniform meshing of the threads at both ends can prevent uneven stress in the support system or bridge joints.

Product parameters

| Mon | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| b1 min | 3.4 | 4.4 | 5.4 | 7.25 | 9.25 | 11.1 | 15.1 | 18.95 | 22.95 | 26.95 | 31.75 |

| b1 max | 4.06 | 5.06 | 6.60 | 8.75 | 10.75 | 12.90 | 16.90 | 21.05 | 25.05 | 29.05 | 33.25 |

| ds | 2 | 2 | 3 | 4 | 4 | 5 | 7 | 9 | 11 | 13 | 15 |

Advantages

The type B double end studs is its strong adaptability. Because the lengths of the threads at both ends are different, a thicker base component can be screwed in on one side, and a thinner part can be fixed with a nut on the other side, without the need for additional washers. For instance, when fixing the equipment base, the short end is screwed into the concrete foundation, and the long end passes through the back cover and is tightened with a nut. The operation is simple.