Double Ended Wheel Stud With Knurled

Send Inquiry

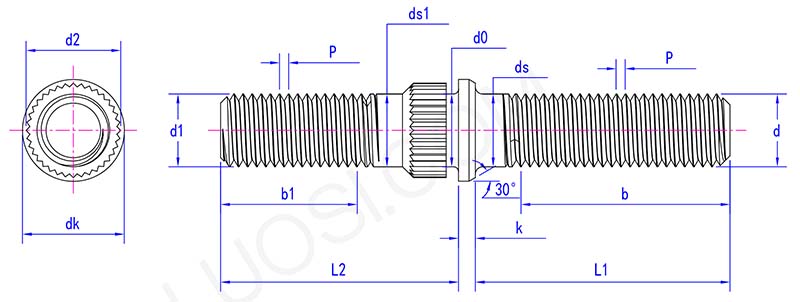

The double ended wheel stud with knurled is in the form of a straight cylindrical "rod" and is a stepped variable diameter structure. Both ends are processed with external threads, and there is a knurled/toothed structure in the middle, which can increase friction.

Product parameters

|

Mon |

M14 | M16 |

| P | 1.5 | 1.5 |

|

b1 |

14 | 16 |

|

d1 |

14 | 16 |

|

ds |

13 | 15 |

|

d2 |

15 | 17 |

|

d0 |

14 | 16 |

|

ds1 |

14 | 16 |

|

dk |

21 | 24 |

|

k |

5 | 6 |

Product Features

The double ended wheel stud with knurled can be precisely adapted. It can be well adapted to many key components in the car. The size specifications are strictly in accordance with the JIS/JASO C610-3-1979 industry standard to ensure the tightness and stability of the installation. It can adapt to different usage environments.

This knurled double ended wheel bolt is standard fasteners used for non-critical automotive parts. Their characteristic is that there is a longitudinal protruding rib (central rib) extending below the bolt head. When tightened, the protruding rib will slightly bite the mating surface, which helps prevent loosening caused by vibration. For example, engine hoods, brackets or interior parts.

When installing the double ended wheel stud, please tighten them to the specified torque. The central rib accomplishes its work by slightly deforming and embedding into the surface. Excessive tightening can crush softer materials (such as plastic brackets), while insufficient tightening can cause the ribs to fail to be clamped correctly. Please use the torque wrench as prescribed.

When replacing the double ended wheel stud with knurled, please be sure to select bolts that exactly match the grade (third class) and size. Using bolts with lower strength may cause breakage. Bolts with higher strength may cause excessive wear or damage to components. The middle rib is of vital importance, and even smooth bolts are difficult to effectively prevent loosening. Please refer to the maintenance manual for the correct specifications.