Double Ended Wheel Stud

Send Inquiry

The double ended wheel studs are in the shape of straight cylindrical rods. Both ends are processed with external threads, and there is a distinct ridge-like protrusion in the middle, which is its signature design. We have different sizes for your selection.

Features and applications

The wheel stud is high strength and stability. Because cars encounter various complex situations during driving, such as jolts, sudden braking and sharp turns, at this time, the bolts must be able to withstand great tensile and shear forces. The ridge design in the middle of this type of bolt can better hold the component in place when tightened, prevent the bolt from loosening, and reduce faults caused by bolt issues.

The double ended wheel studs are made of high-grade alloy steel and have undergone heat treatment, featuring the highest strength and fatigue resistance. It has excellent anti-corrosion performance and is usually coated with zinc sheets (such as Geomet or Dacromet) or phosphate/oil coatings. This can prevent the erosion of heat, liquid and road salt under the hood.

Thees wheel studs are used to fix key high-stress components. They are widely used in engines, gearboxes and suspension systems and can withstand extreme forces. The protruding central rib interlocking surface below the bolt head prevents loosening due to vibration. They are not universal fasteners. They are suitable for connections where failure is not allowed.

The double ended wheel studs are used to fix the steering rack brackets. It can be firmly fixed to the subframe or crossbeam. The ribs can firmly grasp the threads and resist the continuous pushing and pulling forces generated by steering and road surface impact. If these bolts are loose, your steering will feel sluggish and may even break.

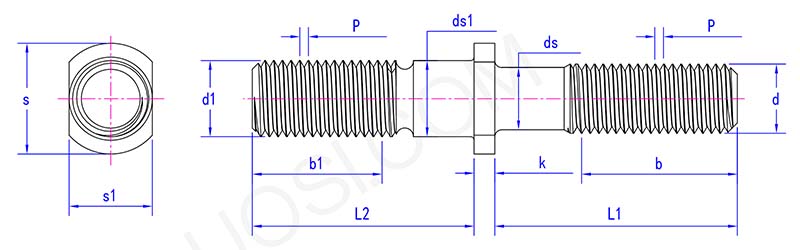

Product parameters

|

Mon |

M16 | M20 |

|

P |

1.5 | 1.5 |

|

b1 |

18 | 22 |

|

d1 |

M18 | M22 |

|

ds |

15 | 19 |

|

ds1 |

18 | 22 |

|

s |

26 | 30 |

|

s1 |

20 | 24 |

|

k |

4.5 | 5 |