Type A Double End Studs

Send Inquiry

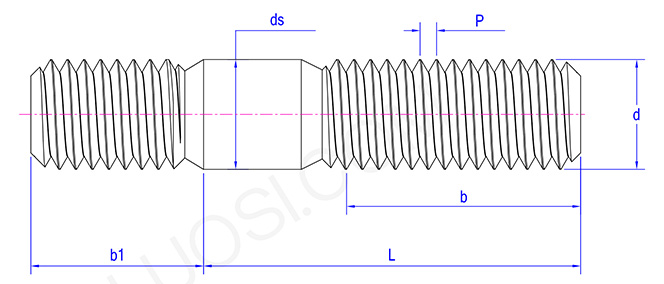

The thread lengths at both ends of type A double end studs are the same, and the middle part is a smooth rod without threads. Common ones include carbon steel and stainless steel, which can meet your different application scenarios. They comply with the implementation standard of GB/T 900-1988.

Features

The middle part of A type double end studs has no thread. The smooth shaft handle enables the parts to rotate or move slightly without getting stuck in the threads. They can be used for connecting rods, pivot points or any situation where motion control is required, such as suspension joints or conveyor rollers.

Type A double end studs can prevent thread engagement. The smooth shaft handle can prevent the threaded ends from coming into contact. This is crucial for stainless steel components where friction can cause cold welding. They are often used in food processing or as ship parts.

Product parameters

| Mon | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 |

| P | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 |

| b1 min | 26.95 | 31.75 | 34.75 | 38.75 | 42.75 | 46.75 | 52.5 | 58.5 | 64.5 | 70.5 | 76.5 |

| b1 max | 29.05 | 33.25 | 37.75 | 41.25 | 45.25 | 49.25 | 55.50 | 61.50 | 67.50 | 73.50 | 79.50 |

| ds max | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 |

| ds min | 13.75 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 |

A type double end studs allow sedimentation. The smooth rod body can withstand slight displacement of concrete or steel without bending the threaded part. Used for the base plate of tall equipment. They are not suitable for corrosive crevices. The exposed shaft may accumulate moisture between the components. So please use or apply anti-sticking agent in dry areas. In a humid environment, please use studs of other models.

One of the features of type A double end studs is that the threads at both ends are of equal length. Thus, whether connecting two components of the same thickness or components of different thicknesses, the force can be evenly distributed and the connection is more reliable. Another feature is its simple structure. There is no complex design. It is just a threaded rod with a low production cost. Moreover, it is convenient to use and neither installation nor disassembly is troublesome.