Type 3 Double End Studs

Send Inquiry

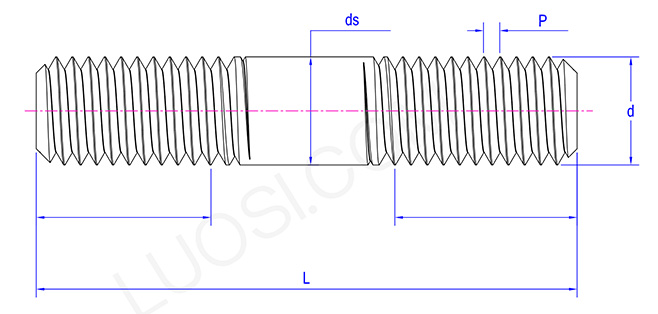

One end of the Type 3 double end studs thread is a coarse thread, and the other end is a fine thread. This design can meet different installation requirements. The thread diameter ranges from M6 to M30, and the length can be selected according to the actual situation.

title=

Product details

In the mechanical manufacturing and automotive maintenance industries,type 3 double end studs are widely used. When manufacturing machinery and assembling some large equipment, it is necessary to connect parts of different materials and thicknesses. This kind of stud can come in handy. When a car is under repair and components such as the engine and transmission are replaced, it is often used to fix them and ensure that the repaired vehicle can operate normally.

The connection of many large components requires type 3 double-ended studs. In factories, large-scale mechanical equipment such as heavy-duty machine tools and injection molding machines are assembled and used. For instance, when installing the worktable of a machine tool, screw the coarse thread end of the stud into the machine tool bed, pass the fine thread end through the installation hole of the worktable, and then screw on the nut.

Type 3 double-ended studs are used for fixing car engine maintenance. When repairing a car engine, it is often necessary to replace some parts, such as the cylinder head. Screw the coarse thread end into the cylinder block and the fine thread end through the cylinder head, and then tighten the nuts in the specified sequence and with the prescribed force. This can ensure a good seal between the cylinder head and the cylinder block.

Product parameters

| Mon | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 |

| P | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 12|18|24 | 11|18|24 | 10|16|20 | 9|14|20 | 8|12|20 |

| ds max | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 |

| ds min | 0.2408 | 0.3026 | 0.3643 | 0.4258 | 0.4876 | 0.5495 | 0.6113 | 0.7353 | 0.8592 | 0.983 |

| b min | 1 | 1.125 | 1.25 | 1.375 | 1.5 | 1.625 | 1.75 | 2 | 2.25 | 2.5 |

Product selling point

The biggest selling point of type 3 double end studs is its flexibility. Because one end has a thick tooth and the other end has a thin tooth, when a thicker and softer component is screwed in on the thick tooth side, it can be screwed in faster. The fine tooth side can be used in conjunction with the nut, allowing for a tighter tightening and more precise adjustment. Moreover, both ends of it can be tightened. When fixing things, it can generate a great tensile force and is not easy to loosen.