Type 2 Double End Stud

Send Inquiry

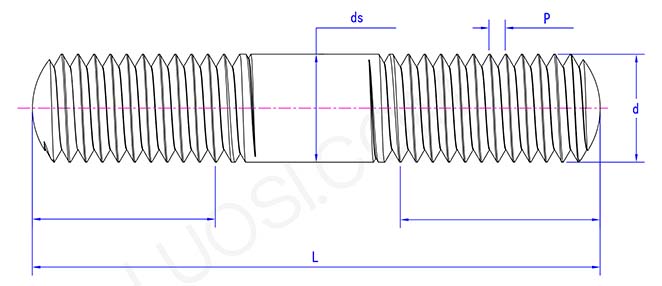

Type 2 double end stud is a common fastener. The middle part of it is called the smooth rod, and its size is approximately the same as the nominal diameter of the thread. The thread complies with the 2A grade standard, ensuring high precision and smooth screwing.

Application Scenario

Type 2 double-ended studs are used to fix mechanical equipment components. The large-scale mechanical equipment in the factory, such as large compressors and injection molding machines, are often used during assembly and maintenance. For instance, when installing the cylinder head of a compressor, screw one end of the stud into the threaded hole of the cylinder block and pass the other end through the installation hole of the cylinder head. Then, screw on the nut and tighten it. In this way, the cylinder head can be firmly fixed.

parameters

Type 2 double end studs are used in the industrial manufacturing industry. Such as automobile manufacturing, assembling key components like engines and gearboxes, mechanical processing, fixing the worktables and tool rests of machine tools, and ensuring processing accuracy, etc. There is also the production of chemical equipment, connecting pipelines and reaction vessels, which can ensure the safe operation of the equipment.

Type 2 double-ended studs are used to connect piping systems. Whether it is water pipes, gas pipes, or pipes for transporting various media in industrial production, they can all be used to connect the flanges of the pipes. They can tightly connect two sections of pipes together to prevent leakage.

Product Features

Type 2 double end studs are thread standards, all of which are 2A grade. Whether screwed into the nut or the threaded hole, they can ensure a tight fit and are also convenient for installation and disassembly. It comes in a variety of materials, and different materials can meet different usage environments.

Product parameters

| Mon | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 |

| P | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 12|18|24 | 11|18|24 | 10|16|20 | 9|14|20 | 8|12|20 | 7|12|18 |

| ds max | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 |

| ds min | 0.2127 | 0.2712 | 0.3287 | 0.385 | 0.4435 | 0.5016 | 0.5589 | 0.6773 | 0.7946 | 0.91 | 1.0228 |

| b min | 1 | 1.125 | 1.25 | 1.375 | 1.5 | 1.625 | 1.75 | 2 | 2.25 | 2.5 | 2.75 |