Thick Shank Double End Stud

Send Inquiry

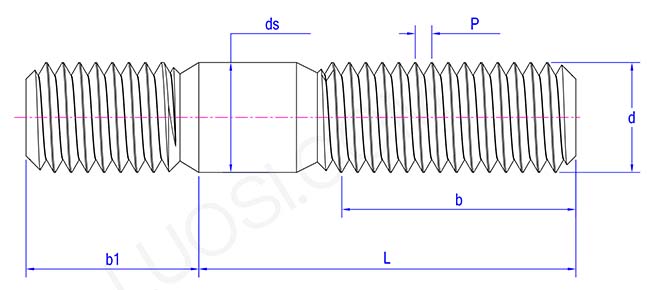

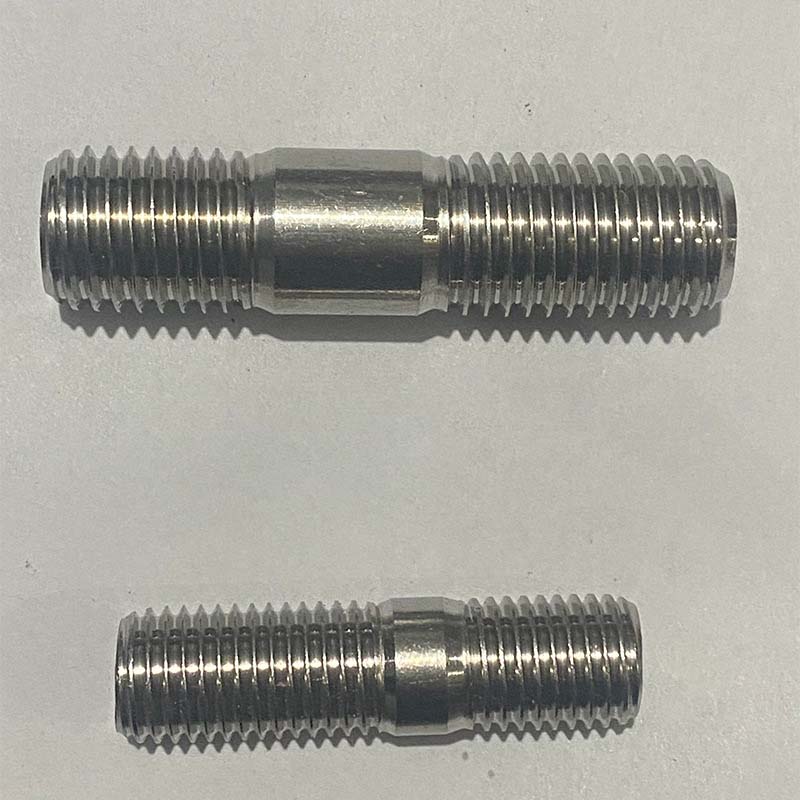

The appearance of a thick shank double end stud is very simple. It is a metal rod with threads at both ends, and the middle part of the rod body is relatively thick. They can cope with relatively harsh environments and have strong anti-rust capabilities.

Product parameters

Product parameters

| Mon | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 |

| P | 1|1.25 | 1.25|1.5 | 1.25|1.5|1.75 | 1.5|2 | 1.5|2 | 1.5|2.5 | 1.5|2.5 | 1.5|2.5 | 2|3 | 2|3 | 2|3.5 |

| b1 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 25 | 30 |

| ds max | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 |

Application

Thick shank double end studs can withstand heavy loads. Its thick middle part will not bend like a standard stud. They are often used to fix the frames of industrial pumps or presses without worrying about breaking under pressure. They are vibration-resistant. Additional materials can suppress the vibration of the generator or conveyor belt. Both ends are equipped with double nuts to achieve a rock-solid connection, which is more durable than fine studs.

In high-temperature areas,this thick shank studs can effectively cope with expansion. More materials can absorb thermal stress without deforming, which is crucial for exhaust manifolds or boiler connections. For temporary rigging, they will not deform. It can be screwed into the anchor point and used together with lifting hardware. It can be reused when the standard stud is under tension.

Thick shank double thread studs can be used for anchoring hydraulic press plates. A 500-ton press requires a sturdy connection. They can anchor the pressure plate to the frame. The thread is screwed into a 60-millimeter-thick steel, and double nuts are used at both ends. The thick handle can eliminate bending during the compression cycle. Loose pressure plates can cause misalignment, resulting in a monthly loss of molds worth $50,000.

Product Features

The middle shank of thick shank double end stud is designed to be relatively thick, which greatly increases its strength and enables it to withstand greater loads. Moreover, thick rods can better resist bending and shearing forces, and perform better than ordinary studs in some complex force conditions.