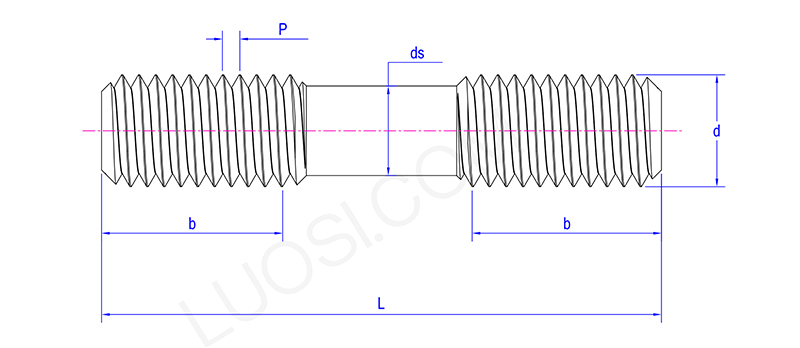

Symmetrically Threaded Double End Studs

Send Inquiry

Symmetrically Threaded Double End Studs are a type of fastener commonly used in various situations. In the construction field, they are often used to connect structural components and help fix buildings together. For example, in high-rise buildings, these bolts will fix and connect steel beams and steel columns. In automobiles, they are crucial for assembling engines together and firmly connecting different engine components. In mechanical manufacturing, double-ended bolts are used in the assembly process of equipment to firmly connect various machine components. Due to their application in numerous industries, these bolts have become an indispensable part of modern manufacturing and construction.

Product Advantages

Symmetrically Threaded Double End Studs are very straightforward in appearance - they are basically long rods with threads at both ends. The threads can be either thick or thin, depending on their intended use. The middle section between threads may be the same thickness as the threads themselves or slightly thinner. This shape makes them easy to install into pre-drilled holes and secure with nuts at both ends, forming a firm connection. Their simple design is suitable for many different fastening operations.

| Mon | M10 | M12 | M14 | M16 | M20 | M24 | M27 | M30 | M33 | M36 | M39 |

| P | 1.5 | 1.75 | 2 | 2 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 |

| ds | 9.03 | 10.86 | 12.70 | 14.70 | 18.38 | 22.05 | 25.05 | 27.73 | 30.73 | 33.40 | 36.40 |

FAQ

Q: What are the primary applications and advantages of using Symmetrically Threaded Double End Studs over other fasteners?

A: Symmetrically Threaded Double End Studs are mainly used to establish a stable and reusable connection between two components with female threads. Their main advantage lies in providing a permanent threaded fixation point, allowing the upper component to be easily assembled and disassembled, which is highly suitable for maintenance work in flange and mechanical applications.