Standard Shaft Retaining Ring

Send Inquiry

To make them work better, standard shaft retaining ring get surface treatments like electro-galvanizing, phosphate coating, or black oxide. These treatments help stop rust, reduce friction, and make them last longer in tough conditions. Stainless steel rings often go through a passivation process to remove tiny iron particles, which helps them resist chemicals better. Special coatings like Xylan or Dacromet add low-friction properties and prevent parts from sticking together in high-speed setups. You can choose different finishes to make them work with lubricants or extreme temperatures, so they’re good for industries like marine engineering or food processing.

Product details:

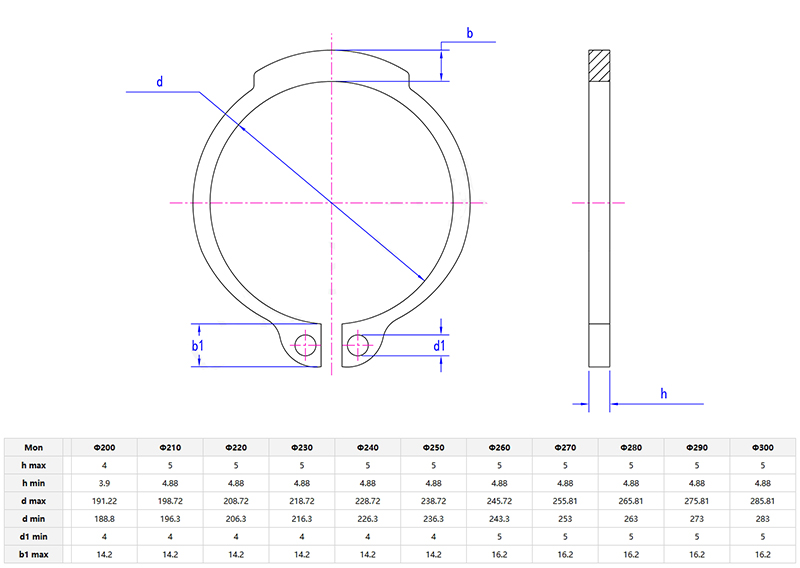

Standard shaft retaining ring come in metric (mm) and imperial (inch) sizes, from 2mm to 300mm. If your shaft has unusual grooves, they can make custom sizes to make sure they fit right. Thickness ranges from 0.5mm to 3mm—thicker ones handle heavier loads. They stick to DIN, ISO, or ANSI rules so they work the same every time.

There are charts showing groove depth, width, and how much force you need to install them. This helps you pick the right ring. Tolerances might be down to ±0.05mm, which is good for jobs where parts need to fit perfectly.

Product parameters

FAQ

Q: Can standard shaft retaining ring be reused after removal?

A: Mostly, you shouldn’t reuse them. They can warp when you put them in or pull them out. All that stretching and squeezing wears out their springiness, so they might not grip parts on the shaft properly.

But if the ring looks fine—no cracks, bends, or weird shapes—you might get away with reusing it for simple, low-pressure jobs. Still, check it under a loupe or magnifier to spot tiny cracks you can’t see normally.

For critical stuff like car gearboxes or machines where failure’s a disaster, just swap in a new ring. Companies sell tools to install them without mangling the rings too much.