Standard Parallel Double Threaded Stud

Send Inquiry

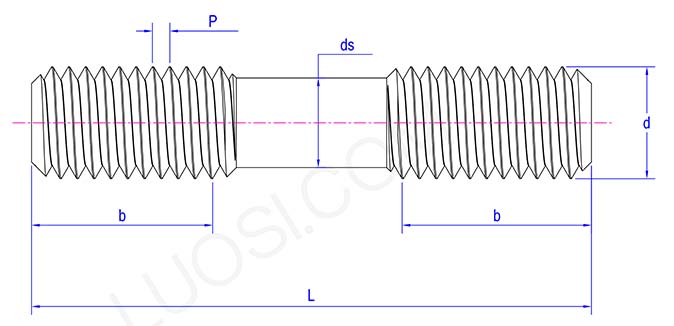

Standard parallel double threaded stud is a common type of fastener. It is a straight metal rod as a whole, with uniform and parallel threads from head to tail on the rod body. It comes in a wide range of specifications, from M8 to M48, and can adapt to various installation scenarios.

Applications

Standard parallel threaded stud is used for leveling the base of industrial pumps. If you want to level the centrifugal pump on uneven concrete, it can solve this problem. Insert it vertically into the holes of the base plate and adjust the nuts at both ends to compensate for the slope of the ground. The same thread allows for precise adjustment of a height of 2 millimeters. An uneven pump will vibrate and damage the seals within three months.

Standard parallel threaded stud can ground the 400A distribution board. Use them to fix the bolts to the distribution cabinet. Connect the two ends of the busbar with nuts. Parallel threads can ensure uniform contact pressure, which is crucial for fault current. Poor grounding can cause an electric arc to be generated during a lightning strike, thereby melting the connection plate.

You can use Standard parallel double threaded stud to fix turbocharger exhaust pipe leaks. They can withstand high temperatures. Install the copper nut between the exhaust flanges. The same thread can absorb thermal expansion without getting stuck. Ordinary bolts will break after 10 cold starts. Missing studs can cause black soot stains to appear on the trailer.

Product parameters

| Mon | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 |

| P | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 |

| ds | 7.19 | 9.03 | 10.86 | 12.07 | 14.70 | 16.38 | 18.38 | 20.38 | 22.05 | 25.05 | 27.73 |

Product feature

Standard parallel double threaded stud has a simple structure and is easy to install. It is a metal rod with parallel threads. It has no complex design, relatively low production cost, and is also very easy to understand. Ordinary workers can operate it after simple training. When installing, just screw one end of the stud into the threaded hole of one component, and then screw a nut or screw the other end into the threaded hole of another component. This can save installation time and labor costs.