Standard Axial Circlip

Send Inquiry

Standard axial circlip are usually made of carbon steel (like SAE 1074/1095) or stainless steel (types 302/316). These give them decent strength and help them last longer under stress. Heat-treated ones can be hardened up to 50 HRC, so they don’t buckle under heavy or shifting loads. Stainless steel is your pick if things might rust, while carbon steel’s cheaper for regular jobs. For fancy cases where you need non-magnetic materials or lighter parts, there’s stuff like beryllium copper or titanium. Either way, the materials make sure these rings meet standards like DIN 471/472 or ISO 8750.

Product details:

Standard axial circlip are used a lot to keep bearings, gears, or pulleys from sliding off spinning shafts. You’ll find them in car transmissions, motors, or big machines. They handle both sideways and push-pull forces, so they’re handy in robots, conveyor systems, or pumps. In planes, they help keep parts from rattling loose in landing gear. Smaller circlips work in tight spots like medical tools or gadgets. They’re quicker to install than nuts or glue, and they’re less likely to fail when things shake a lot.

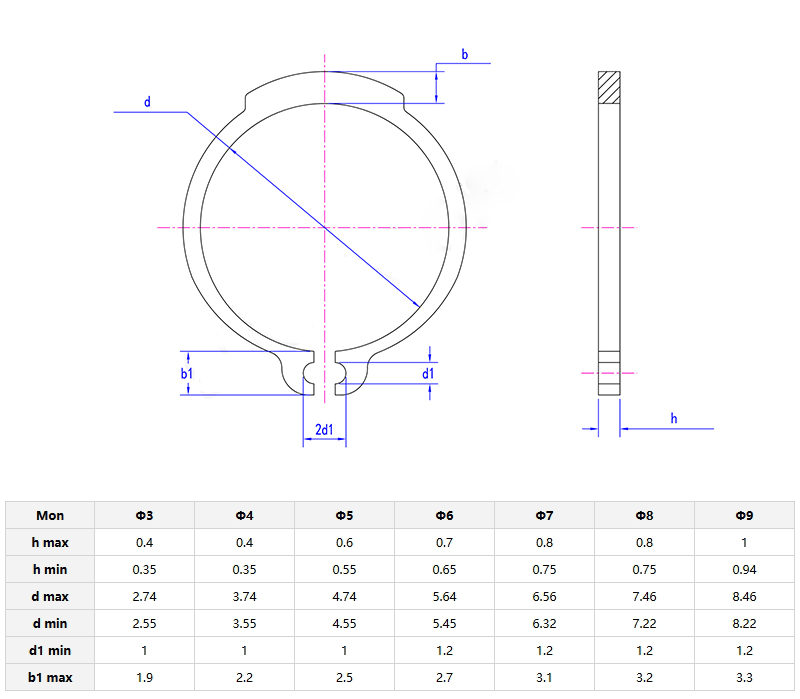

Product parameters

FAQ

Q: How do I select the correct size of standard axial circlip?

A: To get the right size, measure the shaft’s diameter and groove. Use the manufacturer’s charts to match the ring’s inner/outer size to your shaft. Focus on groove depth (needs to fit the ring’s thickness) and how much load it can take.

Too small? It might shake loose. Too big? It could warp the groove. Metric shafts need ISO 8752 rings; imperial ones use ANSI B27.1. Always double-check with calipers—and peek at the guides if you’re stuck. No standard fit? Just order custom ones.