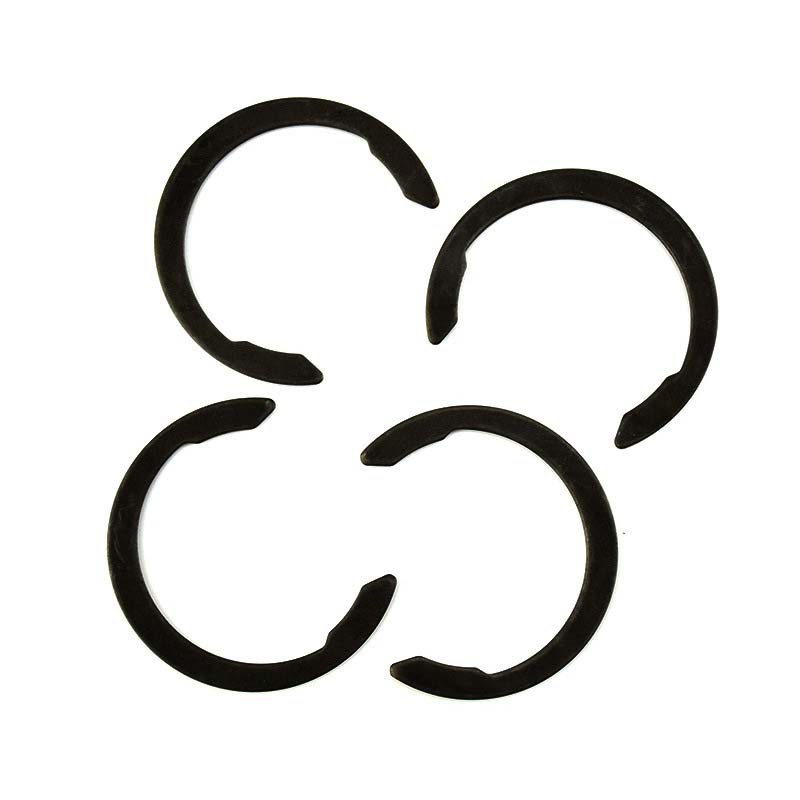

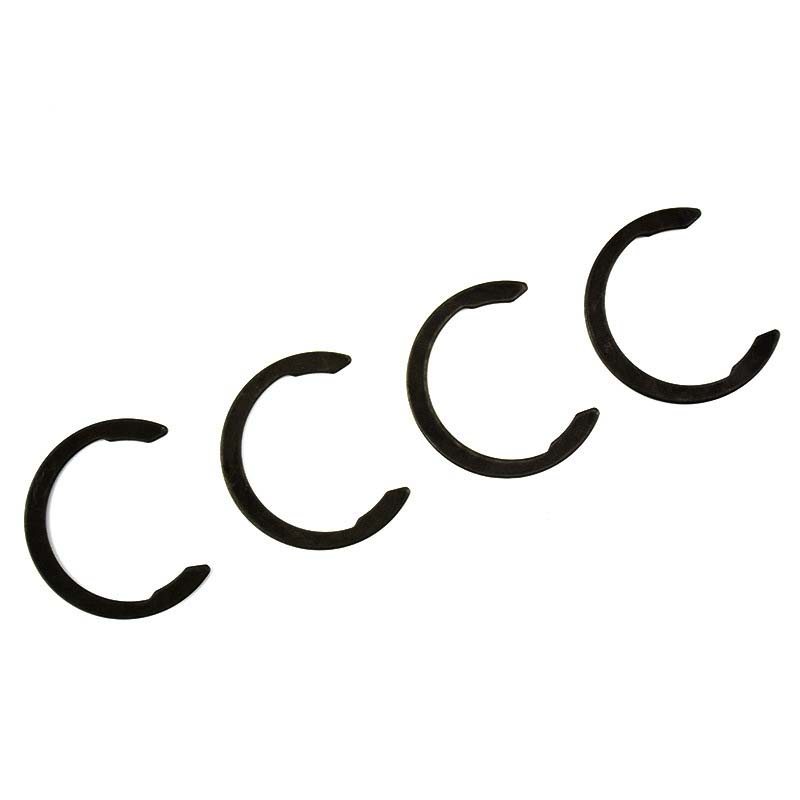

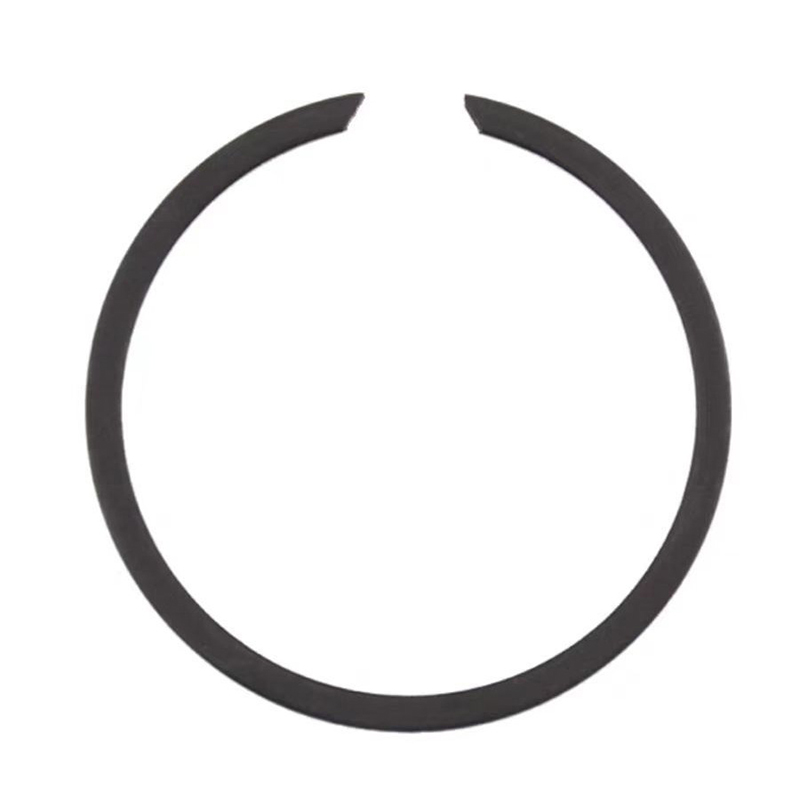

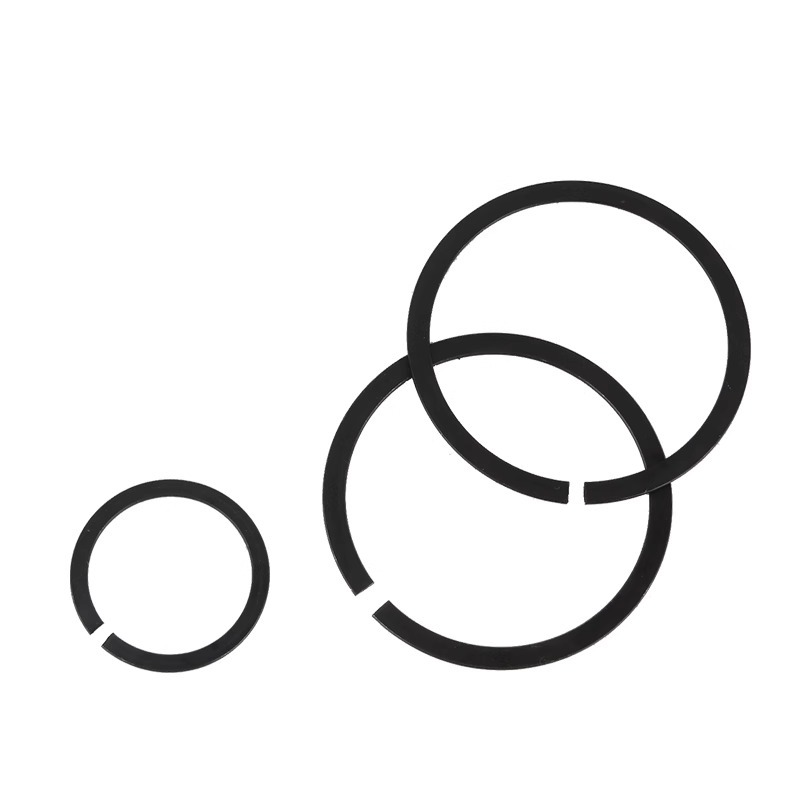

Stainless Steel Spring Retaining Ring

Send Inquiry

Stainless steel spring retaining ring can handle radial loads up to about 1,500 N, and how much they can push axially depends on their design. They last over 10 million cycles under moderate stress. They work in really cold temps down to -70°C (freezing cold) and hot ones up to 400°C (for heat-treated types). Corrosion-resistant versions can stand up to over 500 hours in salt spray tests. Being lightweight (0.5g-200g) cuts down on system drag, which helps with energy efficiency.

Features

The stainless steel spring retaining rings have laser-engraved labels so you can track where they came from. Some have uneven shapes that work better when the weight isn’t spread out evenly. There are also hybrid versions that mix metal centers with plastic coatings to stop electricity from passing through. Some smart ones even have sensors built into them that track stress in real time.

Certifications and Standards

Q: What certifications or testing standards apply to stainless steel spring retaining ring for international exports?

A: It shipped overseas gotta follow specific rules. They need to stick to ISO 8750-8752 (those are the basic ring standards), plus RoHS (no toxic stuff allowed) and REACH regs. Suppliers have to provide paperwork like Mill Test Reports to prove what materials they used, and run tests,like salt spray tests (ASTM B117) to see if they rust or fatigue tests (ISO 15654) to check lifespan.

Depending on the industry, they might need extra stamps,such as, IATF 16949 for cars or AS9100 for aerospace stuff. When shipping to different countries, suppliers should include docs that match local rules, like CE marks for Europe or JIS for Japan. Staying upfront about these rules helps the rings clear customs faster and makes buyers feel confident they’re getting safe, reliable parts.

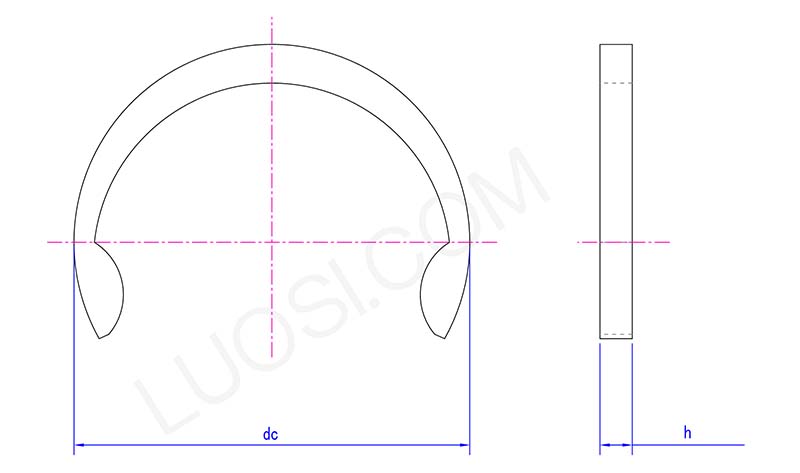

|

Mon |

Φ15 |

Φ16 |

Φ17 |

Φ18 |

Φ19 |

Φ20 |

Φ22 |

Φ23 |

Φ24 |

Φ25 |

Φ26 |

|

dc max |

18 | 19 | 20 | 21 | 22 | 23 | 25 | 26.3 | 27.6 | 29.2 | 30 |

|

h min |

0.97 |

0.97 |

0.97 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

|

h max |

1.03 |

1.03 |

1.03 |

1.23 |

1.23 |

1.23 |

1.23 |

1.23 |

1.23 |

1.23 |

1.23 |