Cost Effective Snap Rings

Send Inquiry

Quality checks for Cost-effective Snap rings happen at every step of making them. First, the raw materials are thoroughly tested to ensure that all indicators meet the preset standards. Then, the entire manufacturing process (covering key processes such as stamping and heat treatment) is strictly monitored to ensure the consistency and stability of the production process.

They use good equipment to test things like size accuracy, how hard the metal is, and how much pulling force it can take. They also use statistical process control (SPC) methods to keep the quality high.

Only the batches that pass all these tests get the okay to be shipped out.

Basically, they don’t skip any checks. From the materials they start with to the finished rings, everything gets tested. If a batch fails even one test, it doesn’t get sent out.

Quality Assurance

Before any batch of Cost-effective Snap rings leaves the factory, they go through a full quality check.

First, someone looks at them to spot any obvious defects—like dents or messed-up edges. Then they check the sizes with tools like micrometers and optical comparators to make sure they’re right. They also test how well they work, like seeing how much weight they can hold without breaking.

Automated systems do a lot of this checking too—they’re fast and accurate, so nothing gets missed. They also pick random Cost-effective Snap rings from the batch to test, which lets them make sure the whole batch is good.

This final check before shipping means only perfect Snap rings get sent to customers.

Basically, nothing leaves the factory without being looked over, measured, and tested. They use tools and machines to be sure, and only the ones that pass every check go out.

| Mon |

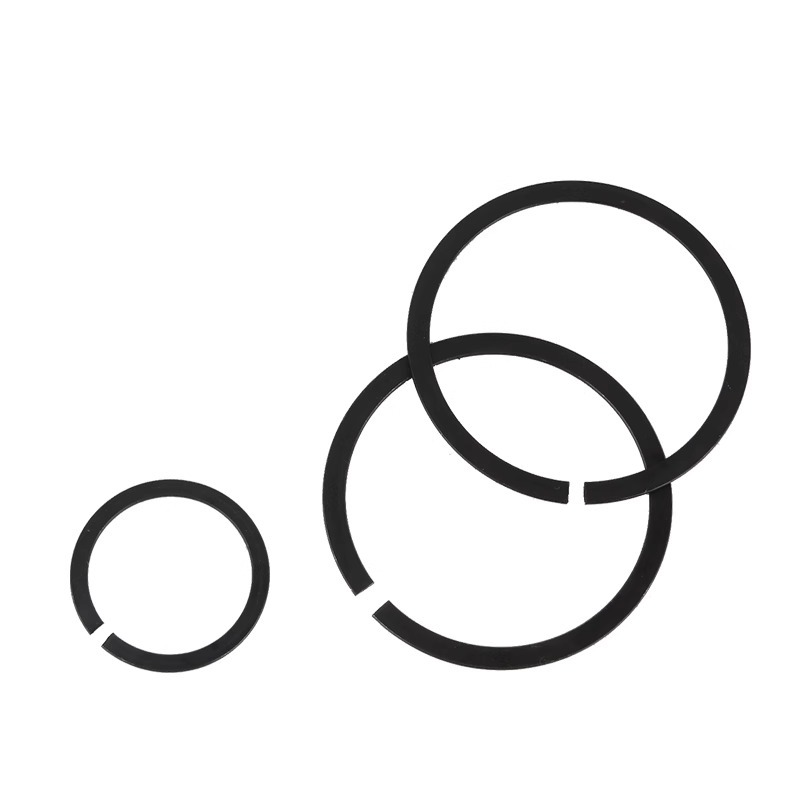

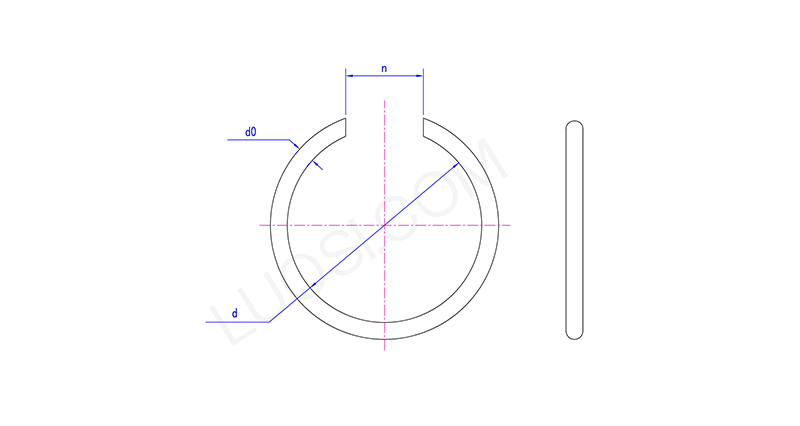

Φ4 |

Φ5 |

Φ6 |

Φ7 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

Φ18 |

Φ20 |

| d0 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

Φ0.8 |

1 | 1 | 1.6 | 1.6 | 2 |

| d max | 3.5 | 4.5 | 5.5 | 6.3 | 7.3 | 9.3 | 11.1 | 13.1 | 14.6 | 16.6 | 18.35 |

| d min | 3.3 | 4.3 | 5.3 | 6.1 | 7.1 | 9.1 | 10.9 | 12.9 | 14.4 | 16.4 | 18.05 |

| n | 2.5 | 2.5 | 2.5 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 10 |

Q: Are your Cost-effective Snap rings reusable, or are they designed for a single application?

A:While our high-quality Snap rings are designed for secure retention, they are generally considered reusable if removed carefully with the proper tools without causing deformation or stress damage. However, we always recommend inspection before reinstallation to ensure performance integrity.