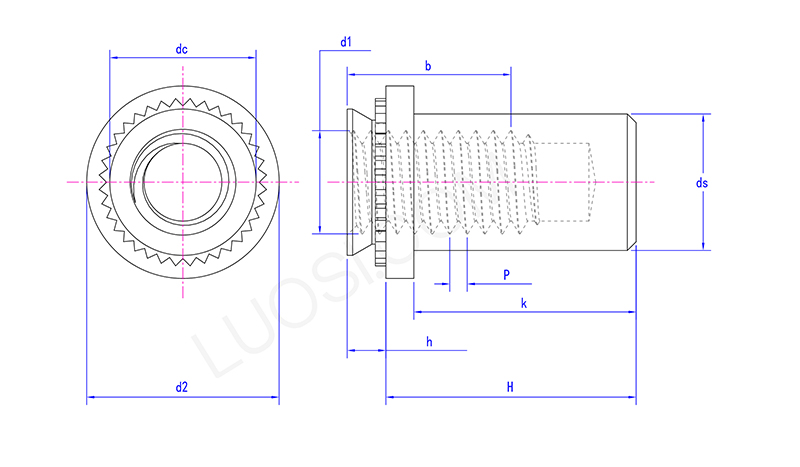

Stainless Steel Sealing Clinching Nut

Send Inquiry

The stainless steel sealing clinching nut is widely used in industries that need sealed threaded connections in sheet metal. You’ll see it in electrical enclosures like junction boxes and control cabinets, HVAC systems (ducts and units), car parts (body panels, brackets, fluid tanks), farm machinery, lighting fixtures, and telecom equipment.

Surface treatment process:

To help with rust resistance and suit different environments, the stainless steel sealing clinching nut usually comes with different surface treatments. Common ones are clear or yellow zinc plating (sometimes with trivalent or hexavalent chromate passivation for extra protection), zinc-nickel plating for really tough conditions, phosphating to help paint stick, or non-electrolytic coatings like Geomet® or DACROMET®.

| Mon | M3-1 | M3-2 | M4-1 | M4-2 | M5-1 | M5-2 | M6-1 | M6-2 |

| P | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 0.8 | 1 | 1 |

| ds max | 3.84 | 3.84 | 5.5 | 5.2 | 6.35 | 6.35 | 8.75 | 8.75 |

| dc max | 4.2 | 4.2 | 5.38 | 5.38 | 6.33 | 6.33 | 8.73 | 8.73 |

| b min | 5.3 | 5.3 | 7.1 | 7.1 | 7.1 | 7.1 | 7.8 | 7.8 |

| h max | 0.91 | 1.38 | 0.97 | 1.38 | 0.97 | 1.38 | 1.38 | 2.21 |

| H max | 9.85 | 9.85 | 11.45 | 11.45 | 11.45 | 11.415 | 14.55 | 14.55 |

| H min | 9.35 | 9.35 | 10.95 | 10.95 | 10.95 | 10.95 | 14.05 | 41.05 |

| k max | 8.5 | 8.5 | 9.8 | 9.8 | 9.8 | 9.8 | 12.7 | 12.7 |

| d2 max | 6.6 | 6.6 | 8.2 | 8.2 | 9 | 9 | 11.35 | 11.35 |

| d2 min | 6.1 | 6.1 | 7.7 | 7.7 | 8.5 | 8.5 | 10.85 | 10.85 |

| d1 | M3 | M3 | M4 | M4 | M5 | M5 | M6 | M6 |

Compliance with industry standards:

Our stainless steel sealing clinching nuts are made to match the specific sizes and performance needs in the UN standards, like the NASM 25027 or MS25027 types. While our factory has certifications like AS9100 (for aerospace) or ISO 9001, the UN sealing clinching nut-Stainless steel parts themselves are built to those UN specs. This basically means they'll fit where they should, quality is the same every time, and they'll hold up in demanding jobs needing a sealed, permanent stainless steel fastener that won't leak.