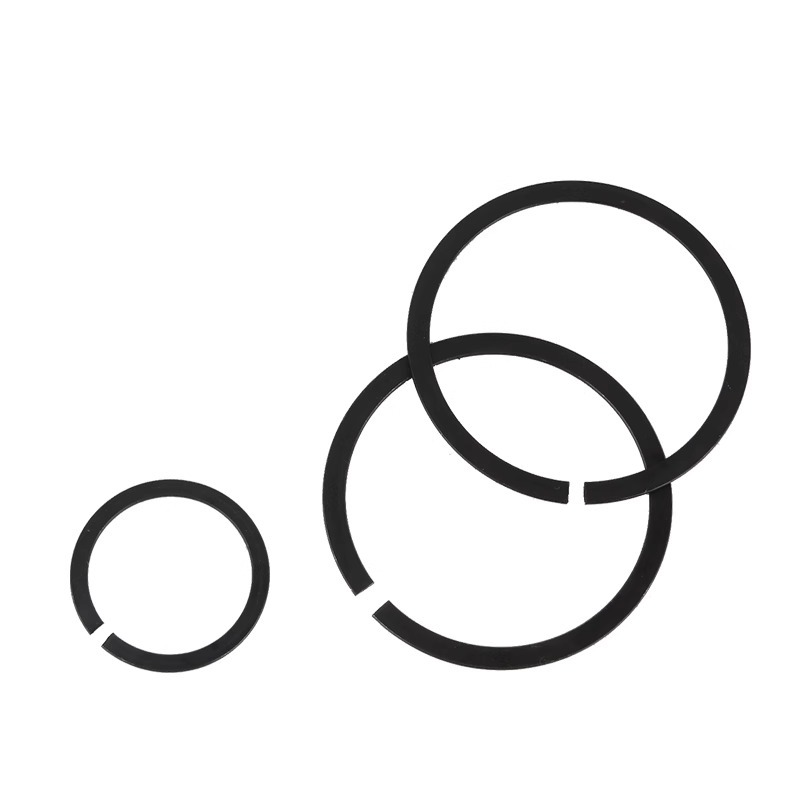

Spring Retaining Rings

Send Inquiry

Spring retaining rings are like specially made clips. They’re designed to hold parts in place within axial or radial setups. These circular clips fit into grooves, keeping bearings, gears, and shafts from moving around. There are two kinds: internal and external. They stop sideways movement but are easy to install or remove. They work well in noisy, shaky environments,like in cars, planes, or factory machines,keeping everything stable. The ring has a split design, so it bends a bit but still holds heavy loads without breaking.

Advantage

The biggest plus of spring retaining rings is that they’re a cheap and light way to hold parts in place. Unlike fasteners with threads, you don’t need complicated machining steps,they cut down on assembly time. Their small size means they save space, even in tight setups. These rings push evenly in all directions, which helps parts wear less over time.

Materials

Q: What materials are spring retaining rings typically made from, and how do they ensure durability in harsh environments?

A:Take stainless steel ones,they’re good for wet or salty areas because they have chromium, which kinda blocks rust. High-carbon steel rings get heated up a bunch to make them harder and tougher, so they work well in heavy jobs like car gears or machines in factories. Sometimes they’ll slap on a zinc coating or do a passivation treatment to help them survive longer. Choosing the right material just means sticking to common standards like ASTM or DIN, so these rings hold up and keep parts secure even in rough setups.

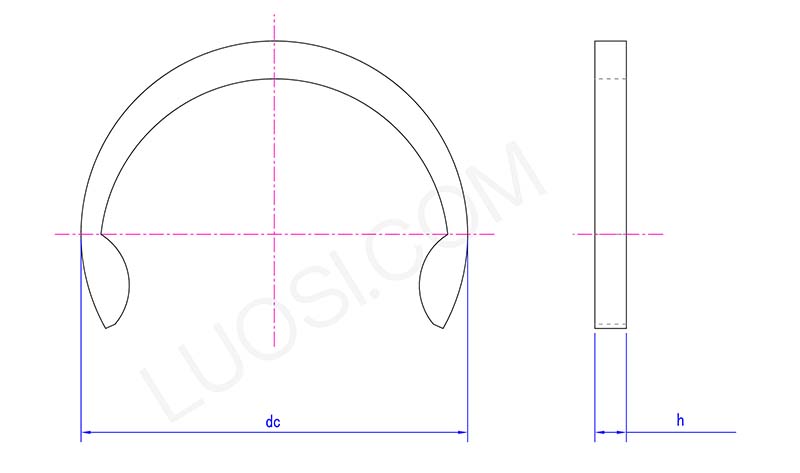

Mon

0.437

0.469

0.5

0.562

0.625

0.687

0.75

0.812

0.875

0.937

1

dc max

0.53

0.57

0.6

0.67

0.74

0.8

0.87

0.94

1.01

1.08

1.15

h min

0.023

0.023

0.033

0.033

0.033

0.04

0.04

0.04

0.04

0.04

0.04

h max

0.027

0.027

0.037

0.037

0.044

0.044

0.044

0.044

0.044

0.044

0.044