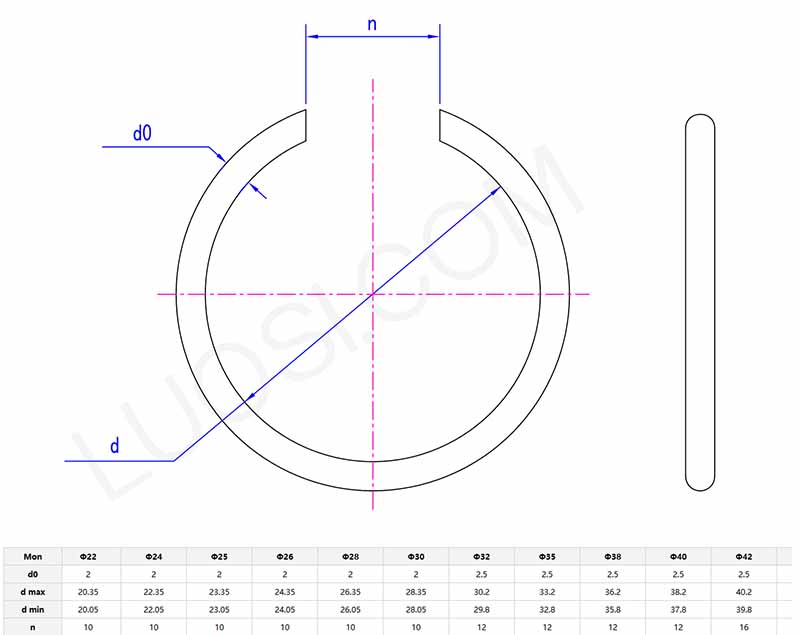

Snap Ring

Send Inquiry

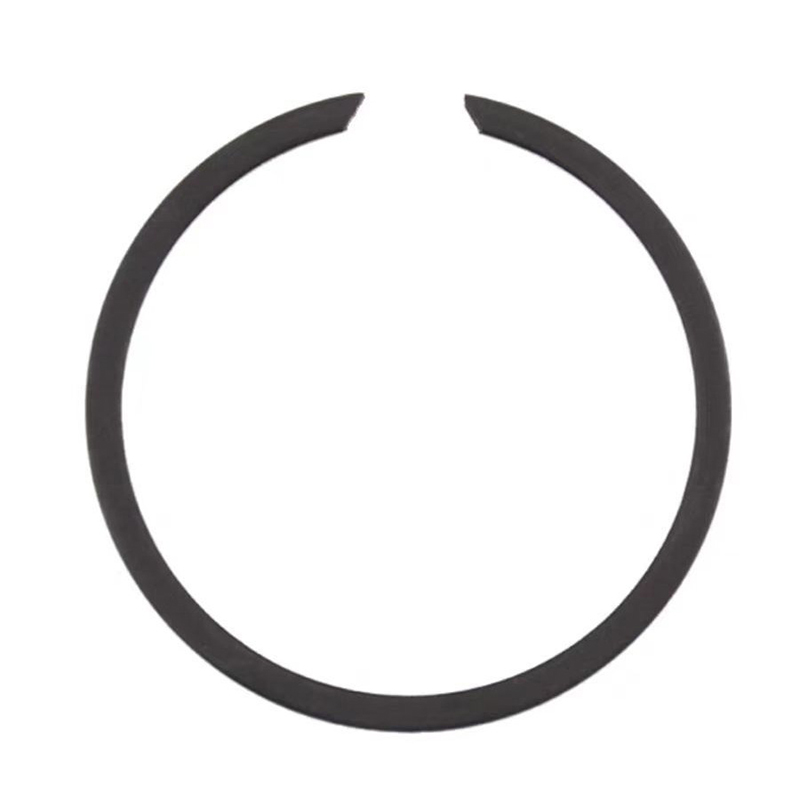

A snap ring is a retaining part made specifically to hold things in place axially inside cylindrical holes.Made of spring steel or stainless steel, its round cross-section helps to evenly distribute stress and reliably bear weight. People use this ring extensively in machinery, automobiles and industrial equipment. They help resist vibration and keep things stable long-term in setups that need high precision.

Features

Snap rings are tough and easy to install. They don’t have sharp edges because of their smooth design, which means they don’t wear down the parts they fit with. They’re strong radially and hold up well to wear and tear, so they work better than stamped rings in setups with heavy loads. You can get them in different sizes and with special coatings to fit different industrial needs. That makes maintenance cheaper and helps equipment last longer.

Materials

Q: What materials are typically used?

A:This ring is made of stainless steel and carbon steel. Stainless steel and carbon steel are durable and have better corrosion resistance than ordinary materials. They are suitable for use in humid or high-pressure environments. Xiaoguo® follows ISO 8752 or DIN 471/472 standards when producing this accessory. Customers will not need to replace it frequently due to quality issues after purchasing and using it.

Applications

Snap rings can be used on mechanical devices such as connecting pins, bearings and gears that need to connect, fix or limit the movement of parts. They are also used in automobiles, such as engines, transmission systems, suspension systems and other parts. In furniture, they can be used in drawer slides and door hinges that need to open and close smoothly to increase spring support. They can also be used in electronic equipment and door and window hinges, as well as the location of door and window switches.