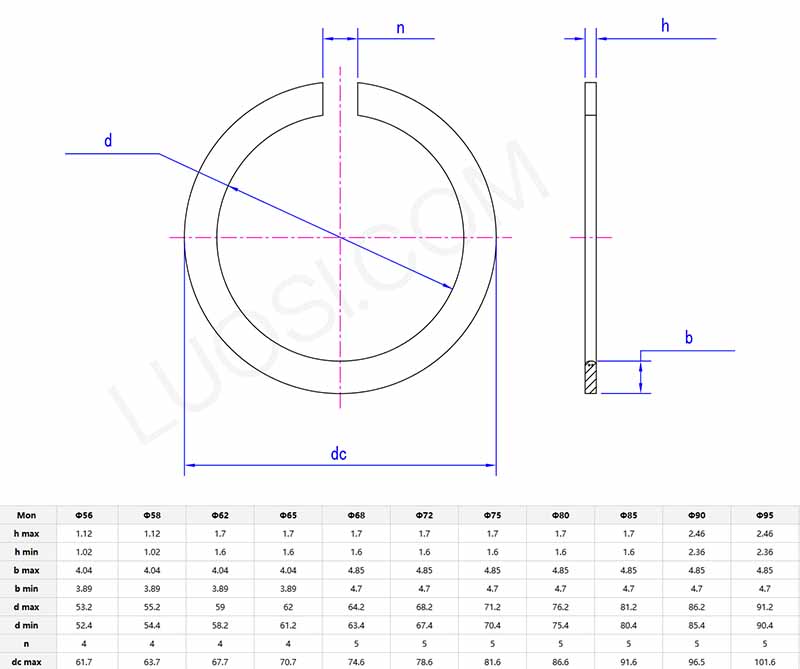

Snap Ring For Bore

Send Inquiry

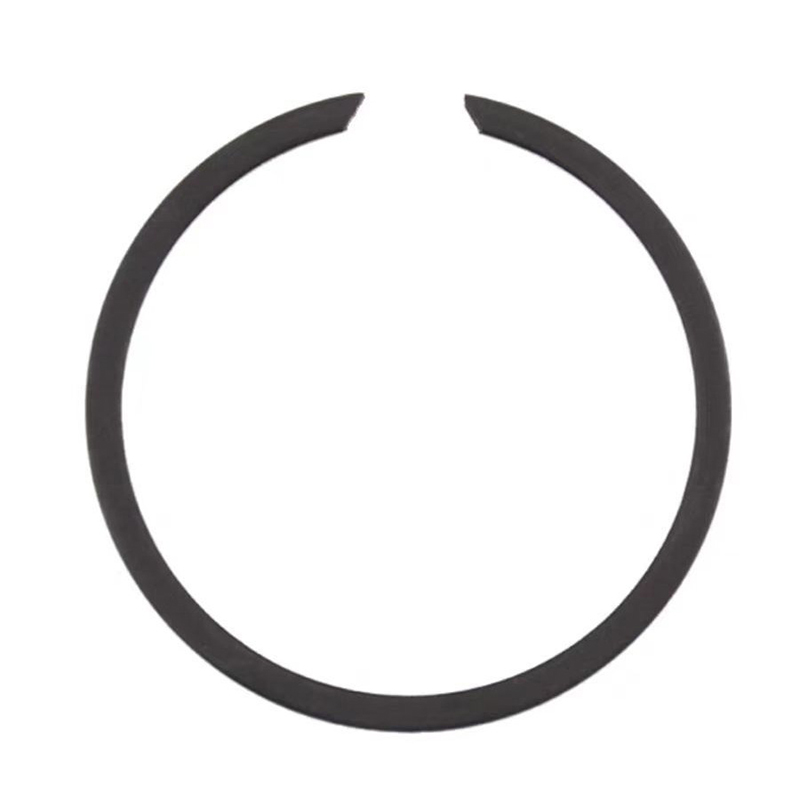

Snap ring for bore have a full circular shape, which cuts down on stress spots compared to C-shaped clips. This design spreads the load evenly all around (360°), lowering the chance of the ring breaking when there's repeated pressure. Because they’re made by shaping wire, they can fit more snugly in holes without making them harder to install.

Features

Snap ring for bore use strong materials, careful manufacturing, and different coatings to offer reliable performance in many industries. Whether it’s farm machinery or precision tools, they solve the problem of keeping parts in place axially while cutting down on assembly time and long-term costs. The products produced by Xiaoguo® comply with ISO 9001 standards. We test the products before shipment to ensure they meet the standards.

Customize

Q: Are custom-designed Snap ring for bore available for non-standard bore sizes or extreme environments?

A: Yes, we can make custom snap rings for special bore sizes, groove shapes, or tough conditions (like high heat or freezing temps). Just tell us your bore diameter, the temperature range it needs to work in, whether the load is pushing axially or radially, and if it’ll face chemicals or moisture.

We might use upgraded materials (like Inconel for high heat) or non-round shapes. Prototypes usually take 4-6 weeks. If your project needs to meet certain standards (like FDA rules for food equipment), let us know so we can make sure it complies.