Sleek Profile Countersunk Head Riveted Nuts

Send Inquiry

The transportation industry - such as high-speed trains, commercial vehicles, and vehicle assembly - extensively uses Sleek Profile Countersunk Head Riveted Nuts. These Sleek-Profile Countersunk head riveted nuts are used in areas like interior panels, floors, and chassis components. Proper alignment and securing are key to ensuring safety, maintaining cleanliness and smooth vehicle operation (of which improved aerodynamic efficiency is an important byproduct). The threads of these nuts can withstand vibrations, so they remain firmly in place even under continuous moving stress. This means the panels can remain securely fixed for an extended period. This usage method requires stable performance, and these nuts can provide such performance - helping to extend the vehicle's lifespan and ensuring passenger safety.

Product Benefits

For the fixation of high-end furniture, industrial machine guards, and building panels, Sleek Profile Countersunk Head Riveted Nuts are a good choice - they are elegant and safe to use. After the component is installed in place, its surface can remain completely smooth without any protruding structures or sharp edges, meeting the surface flatness and safety protection requirements. This is particularly important in situations where safety and design are of utmost importance. This nut can be installed on metal and wood materials; after installation, it will be transformed into a permanent thread insert with stable load-bearing performance to ensure long-term use needs. This makes the assembly and disassembly of components easy, while also maintaining the clarity and continuity of the visual lines.

Product Materials

Our Sleek Profile Countersunk Head Riveted Nuts are available in three materials: steel, stainless steel, or aluminum. When choosing a material, consider the actual application requirements—such as how much strength is required, how much weight it can support, and whether it has the required corrosion resistance.

Aluminum nuts offer a good balance in terms of strength and weight. Stainless steel nuts perform exceptionally well in terms of corrosion resistance. If you need a sturdy and durable material, carbon steel is a good choice. In addition, when selecting a nut, you must ensure that its material matches the material of the parts to be connected. This matching is crucial to the connection effect. This can prevent electrochemical corrosion and ensure that the installed nut maintains reliable performance for a long time.

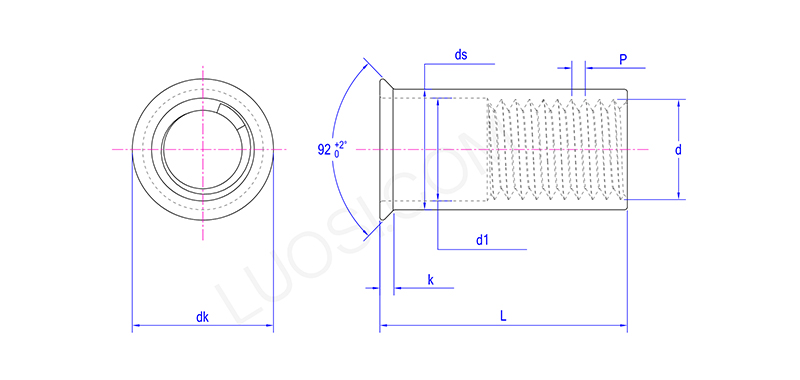

Product Parameters

| Mon | M3 | M4 | M5 | M6 | M8 | M10 | M12 |

| P | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

| ds max | 4.97 | 5.97 | 6.97 | 8.97 | 10.97 | 12.97 | 14.97 |

| ds min | 4.9 | 5.9 | 6.9 | 8.9 | 10.9 | 12.9 | 14.9 |

| d1 max | 4.12 | 4.92 | 5.72 | 7.65 | 9.35 | 11.18 | 13.18 |

| d1 min | 4 | 4.8 | 5.6 | 7.5 | 9.2 | 11 | 13 |

| dk max | 5.5 | 6.75 | 8 | 10 | 12 | 14.5 | 16.5 |

| k | 0.35 | 0.5 | 0.6 | 0.6 | 0.6 | 0.85 | 0.85 |