Round Wire Snap Ring For Shaft

Send Inquiry

To make them work better, round wire snap ring for shaft get surface treatments. For example, zinc plating helps prevent rust, black oxide makes them more resistant to wear, and electropolishing gives them a smooth surface. There are also special coatings like PTFE that cut down on friction in setups where things move fast. These treatments help the rings last longer, reduce issues like metal rubbing and sticking, and make sure they work well with lubricants or in tough conditions.

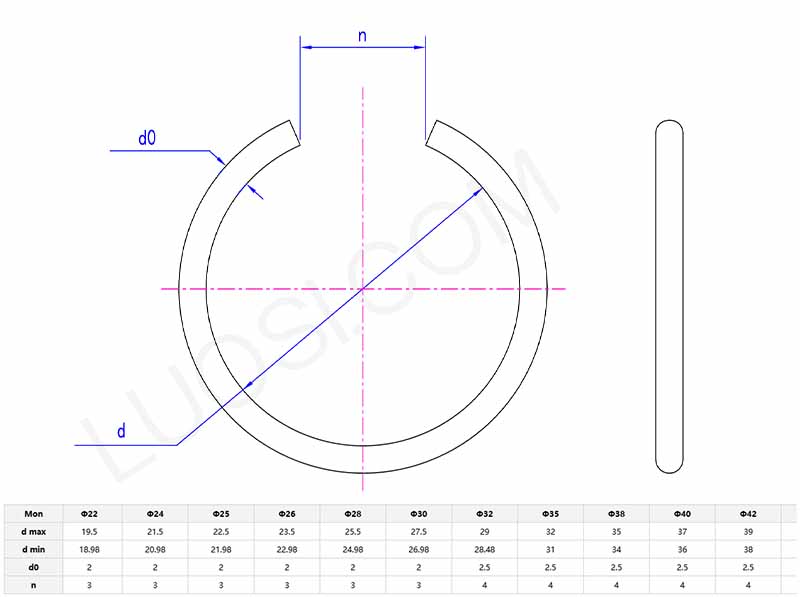

Size

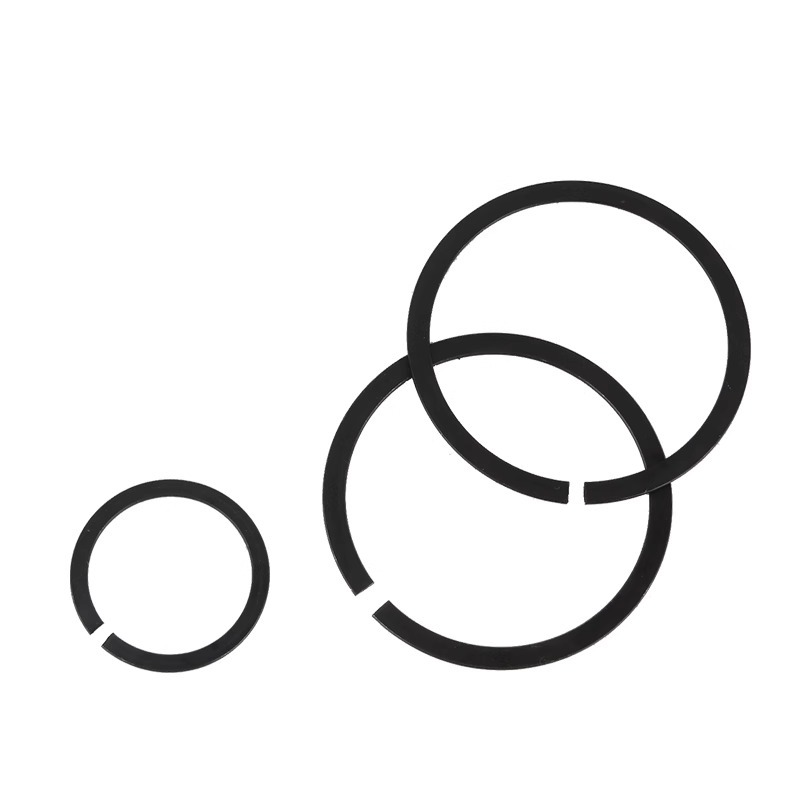

You can get round wire snap ring for shaft in standard sizes (2mm-200mm bore diameters) or custom specs.They follow standards like DIN 471/472 or ISO 1234.The wire diameters are precise (0.5mm-5mm), and the radial thickness is controlled to ensure they fit well. Tolerances are tight (±0.05mm) to keep things consistent in important assemblies, and the designs work with CAD software for easy integration.

Installed

Q: Can round wire snap ring for shaft be installed without specialized tools?

A: While round wire circlips are simple to install, using the right tools, such as circlip pliers (for inner or outer rings), can help prevent the circlip from bending or being installed incorrectly. Without tools, installing a circlip by hand can overstretch it, rendering it ineffective in securing the object.

Before installation, the grooves need to be cleaned, the rough edges need to be smoothed first, and the clamps with appropriate depth and width should be selected.