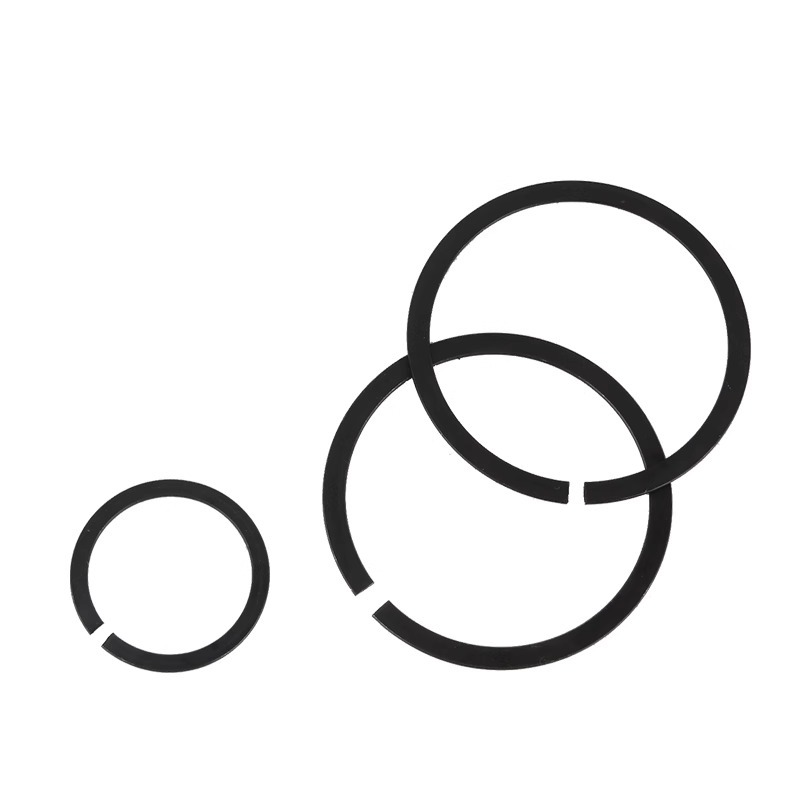

Round Wire Snap Ring For Bore

Send Inquiry

Round wire snap ring for bore is made of carbon steel or stainless steel (such as SAE 1074/1095 or AISI 302/316), which are not easy to rust and have good pressure resistance, can withstand greater pressure and are not easy to break during the tightening process. They are heat-treated to be elastic and can remain tightened even in extremely hot or cold environments. Stainless steel is more suitable in environments with more moisture or chemicals, such as marine components or medical equipment, which often use moisture or cleaning agents. They are tough enough to withstand daily wear and tear, but flexible enough to snap into the groove without breaking. In harsh environmental conditions, stainless steel is more suitable.

|

Mon |

Φ26 |

Φ28 |

Φ30 |

Φ32 |

Φ35 |

Φ38 |

Φ40 |

Φ42 |

Φ45 |

Φ48 |

Φ50 |

|

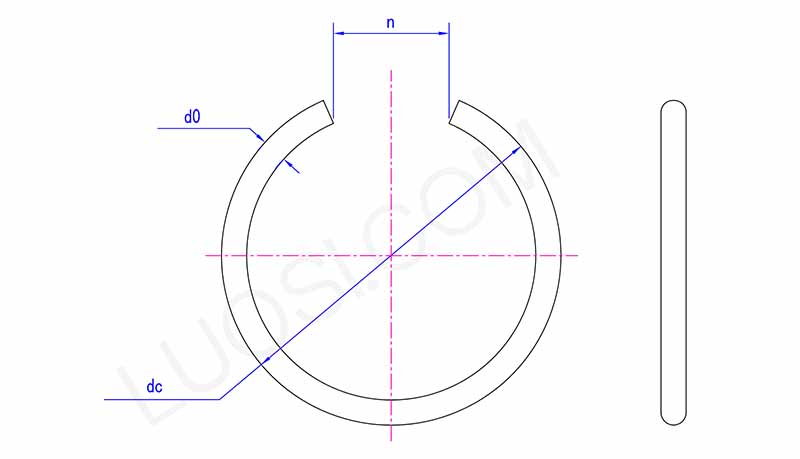

d0 |

2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

|

dc max |

28.8 | 30.8 | 32.8 | 35.5 | 38.5 | 41.5 | 43.5 | 45.8 | 48.8 | 51.8 | 53.8 |

|

dc min |

28.3 | 30.3 | 32.3 | 34.9 | 37.9 | 40.9 | 42.9 | 45 | 48 | 51 | 53 |

|

n |

10 | 10 | 10 | 12 | 12 | 12 | 12 | 16 | 16 | 16 | 16 |

Application

Round wire snap ring for bore is used in transmissions, pumps, bearings and hydraulic systems to secure components such as shafts, pistons and rotors. Their relatively small size makes them ideal for tight spaces such as aerospace, automotive transmissions and robotics where a strong yet lightweight way of securing components is required. They help prevent axial movement of components in rotating devices.

Measuring dimensions

Q: How do I determine the correct size and tolerance of a round wire snap ring for bore for a specific application?

A: To select the right round wire snap ring size, you need to measure the hole diameter, groove diameter (width and depth) and the axial or radial load it needs to withstand. The snap rings produced by Xiaoguo® factory meet the quality standards. The standard size of the outer snap ring follows the DIN 471 standard, and the standard size of the inner snap ring follows the DIN 472 standard, with a tolerance of approximately ±0.05 mm.

Simply provide us with your hole diameter, groove width and depth, and operating temperature, and we can match it to our catalog specifications. If your application is not standard, we can also customize it.

Make sure the free diameter (when not installed) and the tension when installed of the snap ring meet the mechanical stress limits of the component. This prevents it from bending or breaking under moving or changing loads.