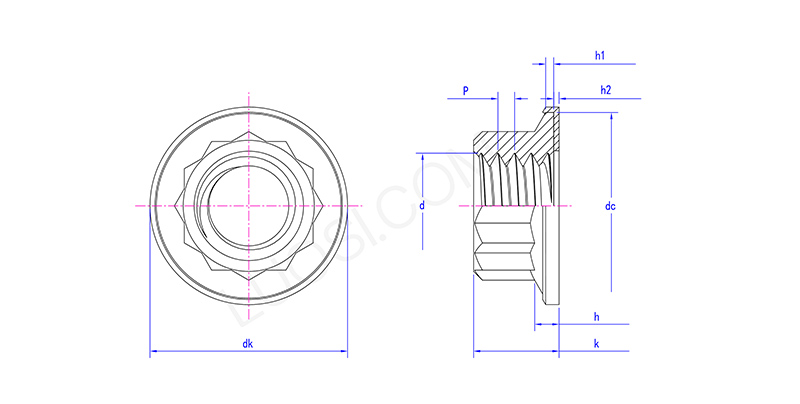

Professional Grade 12 Point Washer Nut

Send Inquiry

For steel structure projects - such as bridges, buildings and transmission towers - Professional Grade 12 Point Washer Nut are crucial for achieving a secure bolt connection. During the assembly of structural components, these components are typically used with ASTM A325 or A490 bolts.

The washer on the nut helps to correct minor deviations. It also protects the steel surface to be connected from scratches (i.e. metal adhesion and scratches) and the bending effect when high torque is applied. This ensures that the entire structure remains stable and safe in the long term, meeting strict engineering standards.

Application Scenario

The renewable energy industry, especially in the manufacturing of wind turbines, relies on Professional Grade 12 Point Washer Nut at critical bolted connections. We are referring to areas such as tower sections, nacelles, and rotor components.

These areas need to withstand a lot of pressure: dynamic loads, extreme weather conditions, and continuous vibration stress. Professional-Grade 12 point washer nut typically have a larger diameter and are made of advanced materials, thus being able to provide the required tightening force and fatigue resistance. Their design ensures a secure installation - you can maintain them and they are also very reliable. This is crucial because this infrastructure needs to be able to operate continuously for several decades.

Product Parameters

| Mon | #10 | 1/4 | 5/16 | 3/8 |

| P | 32 | 28 | 24 | 24 |

| dk max | 0.38 | 0.46 | 0.56 | 0.66 |

| dc min | 0.3 | 0.4 | 0.5 | 0.6 |

| h2 max | 0.023 |

0.023 |

0.023 |

0.023 |

| h2 min | 0.013 |

0.013 |

0.013 |

0.013 |

| h min | 0.056 | 0.06 | 0.09 | 0.102 |

| h1 max | 0.031 | 0.036 | 0.042 | 0.042 |

| h1 min | 0.006 | 0.007 | 0.008 | 0.008 |

| k max | 0.243 | 0.291 | 0.336 | 0.361 |

FAQ

Q:What tools are required to install and tighten your Professional Grade 12 Point Washer Nut?

A:To install our Professional Grade 12 Point Washer Nut, you will need a dedicated 12-point socket or wrench - it is commonly referred to as a double hexagonal or double wedge-shaped tool.

This tool fits perfectly with the shape of the nuts, thus being able to make full contact with the surface of the nuts. As a result, you can safely and easily apply torque. However, using the appropriate size tool is very important - if used improperly, it may cause the tip of the nut to become rounded.

Also, since the Professional-Grade 12 point washer nut already have a washer built-in, you don't need to prepare an additional one. This design not only significantly shortens the assembly process, but also ensures that all components are in the preset precise positions when tightening the nuts.