China Square thin nut Manufacturer, Supplier, Factory

Introduction

High-quality fastening solutions are essential for ensuring the longevity and reliability of mechanical assemblies. Among the various types available, the Square nut stands out for its unique design and robust performance. This specialized component, often referred to as a Square nut, is engineered to provide superior grip and stability in applications where standard hexagonal nuts may not suffice. Its flat sides allow for easy installation with standard wrenches, making it ideal for use in tight spaces or on surfaces that require frequent adjustments. Industries such as automotive, construction, and machinery manufacturing rely on these nuts for their durability and resistance to loosening under vibration. Additionally, the Square nut is compatible with a wide range of bolts and screws, offering versatility across different projects. By incorporating advanced materials and precise manufacturing techniques, these nuts meet stringent quality standards, ensuring they perform reliably in demanding environments. Whether for DIY projects or industrial applications, choosing the right Square nut can significantly enhance the safety and efficiency of your assemblies.

Detailed Specifications

The Square thin nut is meticulously designed to deliver optimal performance in various fastening scenarios. Key parameters include dimensions, materials, and performance ratings, which are critical for selecting the right component. Below is a comprehensive overview of its specifications, presented in both list and table formats for clarity.

Key Features

- Precision-machined for consistent thread engagement

- Available in multiple sizes to fit standard bolt diameters

- Constructed from high-strength materials for enhanced durability

- Surface treatments such as zinc plating to resist corrosion

- Lightweight design for easy handling and reduced assembly weight

Technical Parameters

| Parameter | Value | Unit |

|---|---|---|

| Material Grade | Stainless Steel 304/316, Carbon Steel | - |

| Thread Size Range | M4 to M20 | mm |

| Thickness | 2 to 8 | mm |

| Width Across Flats | 7 to 30 | mm |

| Proof Load | Up to 800 | MPa |

| Surface Finish | Zinc, Hot-Dip Galvanized, Plain | - |

| Operating Temperature | -40 to 400 | °C |

These specifications ensure that the Square thin nut meets industry standards for strength, compatibility, and longevity. For instance, the thread size range allows it to be used with common bolt types, while the material options provide flexibility for different environmental conditions. The proof load rating indicates its ability to withstand high stress without deformation, making it suitable for heavy-duty applications. Surface finishes like zinc plating extend the nut's lifespan by protecting against rust and wear. By adhering to these parameters, users can achieve reliable fastening in automotive frames, machinery mounts, and structural assemblies. Regular quality checks during production guarantee that each Square thin nut delivers consistent performance, reducing the risk of failure in critical systems.

Hot Products

Maintenance Slayer Crown Nut With Slot

Maintenance Slayer Crown Nut With Slot offers a visible and positive locking mechanism, enhancing safety in vital systems. As a committed manufacturer, Xiaoguo® anchors its service promise in timely delivery and dependable supply chain management—two pillars that define its dedication to meeting customer needs for both quality components and reliable support.Cross Recessed Pan Head Thread Rolling Screws-Type Z

Baoding Xiaoguo Intelligent Equipment Co., LTD. is Cross recessed pan head thread rolling screws-type Z manufacturer and supplier in China who can wholesale Slotted pan head screws.The company provides customers with customized product services and sends free samples to customers.Clinching Nut-Carbon Steel

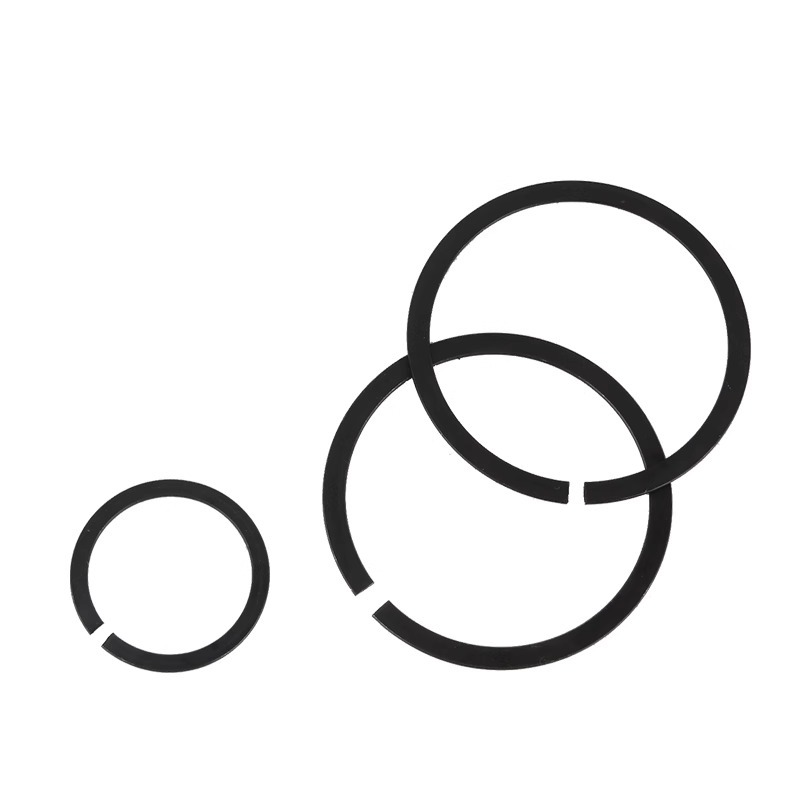

Baoding Xiaoguo Intelligent Equipment Co., LTD. is clinching nut-Carbon steel manufacturer and supplier in China who can wholesale clinching nut-Carbon steel. We can provide professional service and better price for you. If you interested in clinching nut-Carbon steel products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.Easy To Install Snap Rings

Easy To Install Snap Rings are part of Xiaoguo®’s offerings, and its customer support team assists clients including suppliers from inquiry to after-sales service. There are two main types of these snap rings: internal rings for housings and external rings for shafts.Pan Head Stud

Pan head studs are suitable for use in the fields of machinery, electronic products or furniture, especially for components that require smooth round heads. The headplate can evenly distribute the pressure and will not damage the soft materials. Xiaoguo® factory produces durable fasteners, strictly controls raw materials, and conducts quality inspections before shipment.Hexagon Head Bolts With Flange

The hexagon head bolts with flange have a flange and a hexagonal head. Behind the flange is a threaded screw. The flange can disperse the pressure and reduce local pressure.Xiaoguo® factory provides bolts of various sizes and specifications, with fast delivery and guaranteed quality.