China DIN 6926 Non Metallic Insert Self Locking Hexagon Nuts Manufacturer, Supplier, Factory

DIN 6926 Non-Metallic Insert Self-Locking Hexagon Nuts: High-Performance Locking Fasteners

DIN 6926 specifies the requirements for non-metallic insert self-locking hexagon nuts, designed for applications where vibration resistance and secure fastening are critical. These nuts feature a built-in non-metallic locking element that creates consistent friction and prevents loosening under dynamic loads. Ideal for automotive, aerospace, machinery, and structural assemblies, they ensure reliability in demanding environments without requiring additional locking devices.

Key Features and Benefits

- Self-locking capability through a non-metallic insert (typically nylon or polymer)

- Reusability: Can be reused multiple times without significant loss of locking performance

- High vibration resistance: Effective in preventing loosening under cyclic loads

- Corrosion resistance: Available in various coatings and materials for different environmental conditions

- Temperature stability: Suitable for a wide range of operating temperatures

- Easy identification: Often color-coded or marked for quick recognition

Technical Specifications

The following table outlines the standard dimensions and mechanical properties according to DIN 6926:

| Nut Size (M) | Width Across Flats (mm) | Height (mm) | Thread Pitch (mm) | Proof Load (MPa) | Material Grade |

|---|---|---|---|---|---|

| M5 | 8 | 5 | 0.8 | 580 | 8 |

| M6 | 10 | 6 | 1.0 | 600 | 8 |

| M8 | 13 | 8 | 1.25 | 640 | 8 |

| M10 | 17 | 10 | 1.5 | 700 | 10 |

| M12 | 19 | 12 | 1.75 | 720 | 10 |

Material and Coating Options

DIN 6926 nuts are available in various materials and surface treatments to meet specific application needs. Common options include:

- Steel Grades: Carbon steel (grade 8, 10, 12), alloy steel

- Stainless Steel: A2 (304), A4 (316) for enhanced corrosion resistance

- Coatings: Zinc-plated, galvanized, dichromate, or phosphate coatings

- Non-Metallic Insert: Typically nylon or other engineering polymers, ensuring consistent locking force

Performance Characteristics

The self-locking mechanism relies on the elastic deformation of the non-metallic insert, which applies radial pressure on the bolt thread. This design provides several performance advantages:

- Maintains clamping force under vibration and thermal cycling

- Reduces the need for lock washers or adhesives

- Ensures reliable performance in temperatures from -50°C to +120°C (depending on insert material)

- Complies with international standards for quality and safety

Application Guidelines

For optimal performance, follow these installation and usage recommendations:

- Ensure threads are clean and free from debris before assembly

- Use hand tools initially to avoid cross-threading

- Apply torque according to standard specifications; avoid over-tightening

- Inspect the non-metallic insert for damage before reuse

- Select the appropriate material and coating based on environmental exposure

Hot Products

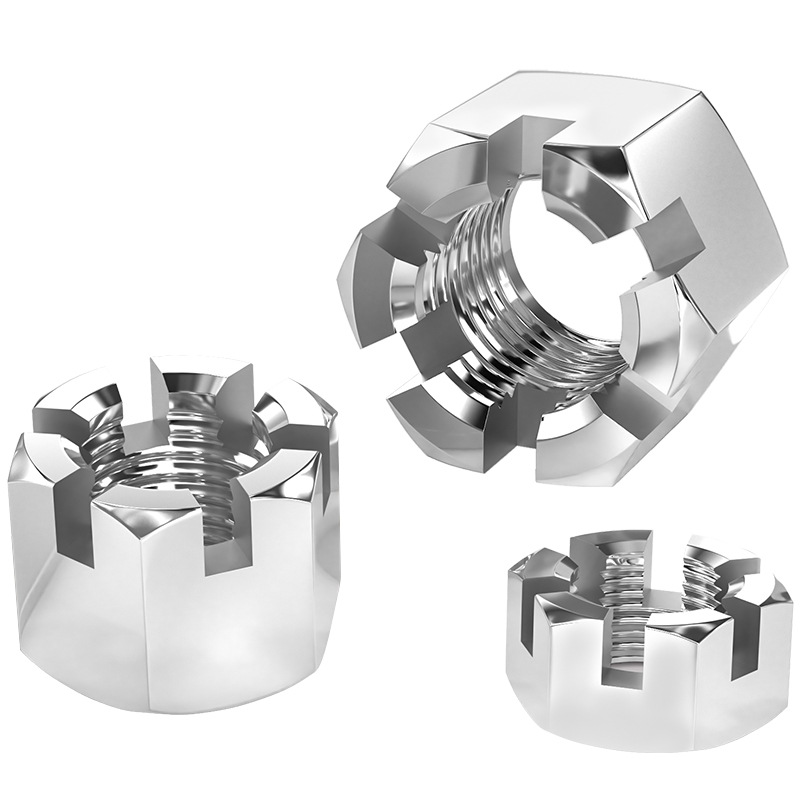

High Torque Crown Nut With Slot

Xiaoguo® specializes in manufacturing and exporting a wide range of industrial fasteners globally. The High Torque Crown Nut With Slot is a specialized type of fastener designed for secure locking applications.Grub Screws With Thrust Point

Baoding Xiaoguo Intelligent Equipment Co., LTD. is Grub screws with thrust point manufacturer and supplier in China who can wholesale Slotted pan head screws. The company provides customers with customized product services and sends free samples to customers.Serrated Lock Washer External Teeth For Assembly

The serrated lock washer external teeth for assembly used for assembly can withstand greater pressure and maintain a firm connection. Serrated lock washers are often used to assemble automobiles and mechanical equipment. As a professional washer manufacturer, Xiaoguo® has an on-time delivery rate of 98%.Professional Grade Hexagonal Wrench

Also known as an Allen key or hex key, the Professional Grade Hexagonal Wrench is a fundamental tool in any mechanic's or technician's toolkit. International supplier trust Xiaoguo® for its consistent quality and dependable supply chain.Groovd Pins-Full-Length Taper Grooved

Baoding Xiaoguo Intelligent Equipment Co., LTD. is Groovd Pins-Full-Length Taper Grooved manufacturer and supplier in China who can wholesale Grooved pins-Full-length taper grooved. We can provide professional service and better price for you. If you interested in Grooved pins-Full-length taper grooved products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.Overload Proof Crown Nut With Slot

Overload Proof Crown Nut With Slot is one of the key components that echo manufacturer Xiaoguo®’s core objective: building long-term partnerships through product excellence. When maintenance work calls for disassembly, this nut and its cotter pin are typically replaced with new components.