Precision Engineered Welding Flange Nut

Send Inquiry

Precision Engineered Welding flange nut come in different colors and surface looks—it all depends on the material they’re made of and the coating used on them.These nuts usually have a few common surface finishes:Silver ones: They’re zinc-plated (meaning a layer of zinc is added to the surface).Yellow ones: They have a zinc chromate finish (treated with zinc chromate to get that color).Black ones: They’re phosphated (coated with a phosphate layer for the black look).There’s also plain stainless steel—this one just keeps the original color of stainless steel, with no extra coating.

Besides fighting rust, the coatings also give a cleaner appearance and help tell different specs apart. Using color coding makes it easier to manage stock and grab the right nut faster during assembly.

The surface finish also improves grip and helps the nuts weld on better, so they stay firmly in place. So the color and coating aren’t just about looks—they actually make the nut more practical and easier to use.

Product details

We ship Precision Engineered Welding flange nut worldwide by air, sea, or through express carriers like DHL and FedEx. We’ll figure out the best way to ship based on how soon you need them, the size of your order, and where it’s headed.

Standard shipping works well if you’re buying in bulk and want to save money, while expedited services are for when you’re on a tight deadline. These nuts are small and not too heavy, so transportation costs stay low. A lot of sellers also offer free shipping if your order is over a certain amount.

You can also track your order live, so you know exactly where your nuts are on the road.

So no matter where you are or how fast you need them, we’ll find a way to get them delivered—and you won’t have to wonder when they’ll arrive.

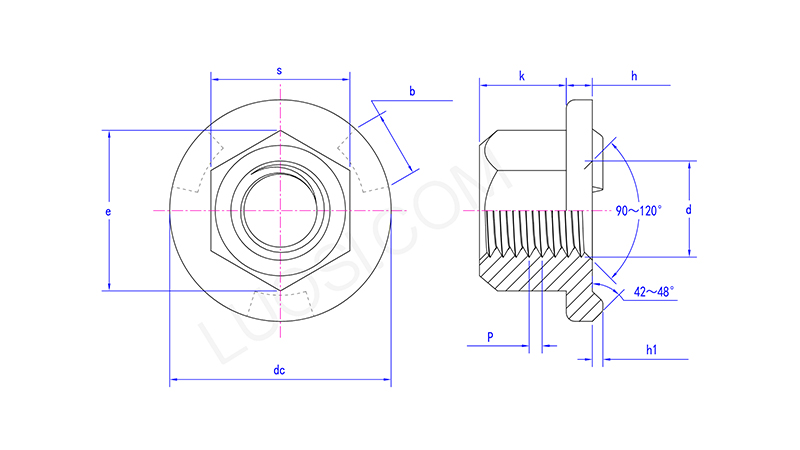

| Mon | M8 | M10 | M12 | M14 |

| P | 1.25 | 1.5 | 1.75 | 2 |

| h1 max | 1.1 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.9 | 1.1 | 1.1 | 1.1 |

| dc max | 22.5 | 26.5 | 30.5 | 33.5 |

| dc min | 21.5 | 25.5 | 29.5 | 32.5 |

| e min | 13.6 | 16.9 | 19.4 | 22.4 |

| h max | 2.75 | 3.25 | 3.25 | 4.25 |

| h min | 2.25 | 2.75 | 2.75 | 3.75 |

| b max | 6.1 | 7.1 | 8.1 | 8.1 |

| b min | 5.9 | 6.9 | 7.9 | 7.9 |

| k min | 9.64 | 12.57 | 14.57 | 16.16 |

| k max | 10 | 13 | 15 | 17 |

| s max | 13 | 16 | 18 | 21 |

| s min | 12.73 | 15.73 | 17.73 | 20.67 |

Q:Can you provide guidance on properly welding the Precision Engineered Welding flange nut?

A:For a secure bond, the surface must be clean. Position the Precision-Engineered Welding flange nut and use a continuous circular weld around the flange's base. Avoid excessive heat to prevent thread distortion. Always consult specific welding procedure specifications for your material.