Precision Engineered Double End Studs

Send Inquiry

Precision Engineered Double End Studs come in various colors and shapes to meet different appearance requirements and application scenarios. When it comes to color, most of them are metallic in color. For example, stainless steel is usually silver-gray, but if it is black oxidized, it will turn black. Some also have a zinc coating, giving them a bright metallic luster.

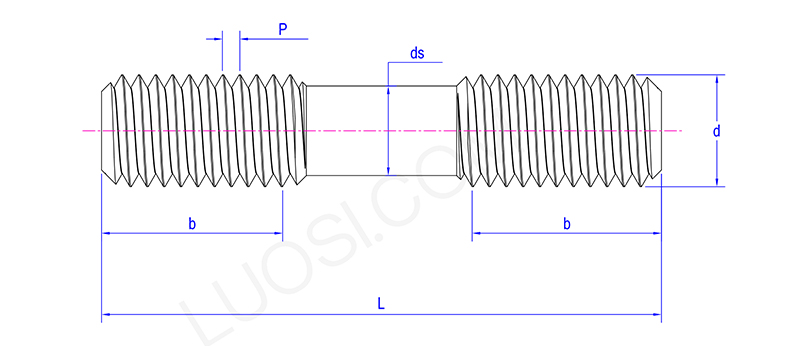

As for shape, most are just straight rods with threads at both ends, but you can also find some with a hexagonal middle section. This makes it easier to grip with a wrench when tightening, allowing for greater tightening force.

These options make it very convenient to select double-ended screws that are both practical and in line with the style of your project.

Mode of transport

We offer you various shipping options through our renowned logistics partners, including Precision Engineered Double End Studs. You can choose express delivery, air freight or sea freight.

For urgent orders, express delivery usually takes 3 to 5 working days. Air freight is also very fast, taking approximately 5 to 7 days.

However, sea shipping will be slower. Due to differences in logistics timeliness in different regions, the arrival time needs to be determined based on your location, generally within the range of 15 to 30 days. But if you order a large quantity, sea shipping can save you more money.

No matter which method you choose, we will track your goods and keep you updated at all times.

FAQ

Q: Can you provide full material traceability and certifications for your Precision Engineered Double End Studs?

A:Sure. We offer complete material traceability services for all Precision Engineered Double End Studs. For each batch of goods, we will provide a rolling test certificate (MTC) in accordance with the requirements of EN 10204 3.1 standard as an important proof of quality compliance. This certificate can verify the chemical composition and mechanical properties of the raw materials, thereby ensuring the quality and compliance of critical applications.

| Mon | M10 | M12 | M16 | M20 | M24 | M27 | M30 | M33 | M36 | M39 | M56 |

| P | 1.5 | 1.75 | 2 | 2.5 | 3 | 3 | 3.5 | 3.5 | 3 | 3 | 4 |

| ds | 9.03 | 10.86 | 14.70 | 18.38 | 22.05 | 25.05 | 27.73 | 30.73 | 33.40 | 36.40 | 52.43 |