Phillips countersunk screw

Send Inquiry

The Phillips countersunk screw adheres to ISO 14583 (recessed head standards) ; DIN 7985 specifications; ASTM F593 for stainless steel fasteners and MIL-SPEC requirements for aerospace applications. RoHS-compliant versions eliminate hazardous substances, while REACH certification ensures eco-friendly production that compliances validate the Star-recessed screw’s reliability, making it a trusted choice for regulated industries like medical devices and renewable energy systems.

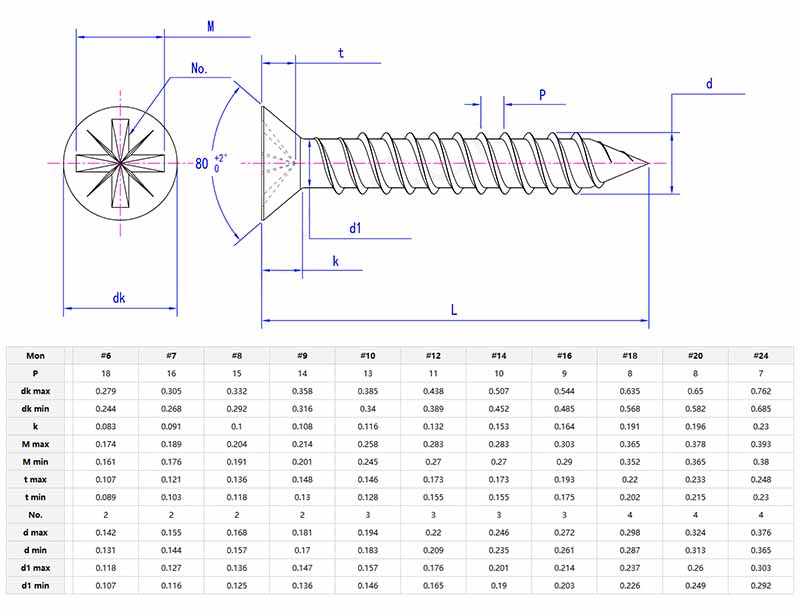

Product details and parameters

The Phillips countersunk screw mixes practical design with new ideas, making fasteners better for all kinds of uses that is star-shaped drive, durable materials, and various coatings mean it works well in many industries. You can use it in delicate electronics or heavy machinery. The flat head looks neat and keeps things secure, while the tamper-resistant design adds protection. We offer products of different sizes and in compliance with international standards, so engineers and manufacturers from all over the world can trust us. They’re a smart, long-lasting choice for anyone who wants quality and efficiency.

FAQ

Q: Do your screw support customized packaging for bulk export orders?

A: We can package Phillips countersunk screw in different ways. For example, vacuum-sealed anti-tarnish bags, ESD-safe reels (which are good for preventing static), or plastic trays that resist vibrations. If you order in bulk (10,000 or more), we use big boxes with humidity indicators and QR codes for tracking. These boxes meet the ISTA 3A shipping standards, so they’re safe for transport.

For OEM/ODM needs, we can add your brand to the packaging, include manuals in multiple languages, and add barcode labels. We also offer Just-in-Time delivery, sending pre-sorted kits directly to assembly lines to make things easier. When shipping internationally, wooden packaging follows ISPM 15 rules, and shipments to the EU meet REACH regulations to stay compliant.