Cross Recessed Screws

Send Inquiry

Cross Recessed Screws come in different materials depending on what you need. You can get them in A2/A4 stainless steel, Grade 5/8 alloy steel, or titanium. The stainless steel types have around 16-18% chromium and 10-12% nickel – that’s what helps them fight rust. The alloy steel versions get heat-treated to make them stronger against shear forces (the kind that tries to snap things apart). Titanium screws are lighter, hold up well, and work safely in medical gear where they might touch skin or implants.

These screws are certified under RoHS and REACH, which basically means they’ve passed international safety checks. No sketchy chemicals – they’re good to use anywhere without environmental worries.

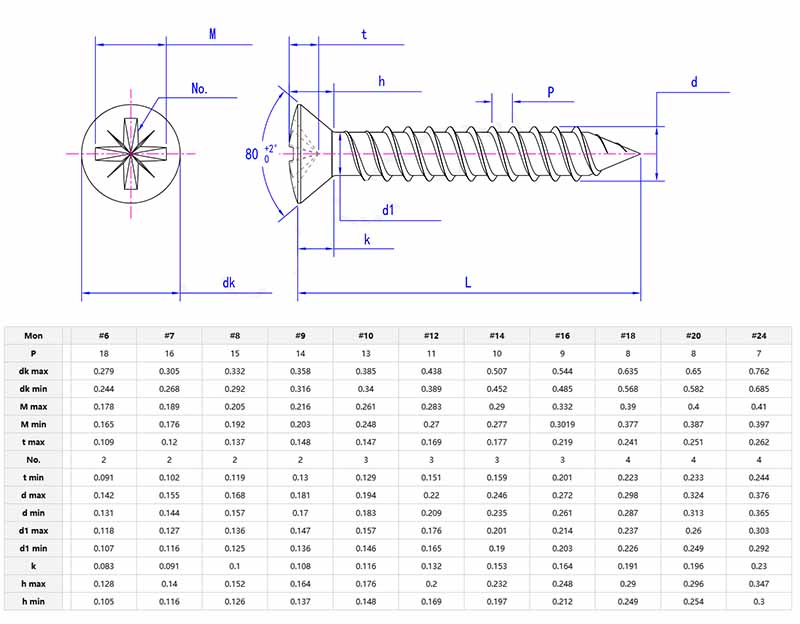

Product details and parameters

To make Cross Recessed Screws last longer, check them often for rust or wear. Use a soft brush to clean the threads and get rid of dirt—don’t use rough tools that might scratch them. If you’re using them in high heat or with different metals (like steel and aluminum), put on some anti-seize lubricant to keep them from sticking. Store the screws in a dry place where it’s not humid to avoid rust. If you want to reuse the screws, please make sure not to tighten them too much. Determine the degree of tightening according to the torque rules we provide. If the screws are bent or the heads are damaged, you need replace them immediately to ensure the safety of all components of the equipment.

FAQ

Q: What surface treatments are available for Screws to prevent rust?

A: We’ve got a few ways to keep Cross Recessed Screws from rusting. Including electro-galvanizing (thinner zinc layer, about 5-8 microns), hot-dip galvanizing (thicker zinc layer,50-80 microns), or Dacromet (a mixture of zinc and aluminum sheets). If the usage environment is extremely harsh, such as there are chemicals or salt water around. We will switch to using xylan or Teflon coatings. These slipperier coatings cut down on friction and ace salt spray tests. The star-shaped groove on the screw head gets coated carefully too, so your screwdriver won’t slip even after tons of use.

These coatings help the screws survive outdoors for 10+ years, and they’ve been tested in salt spray chambers for 1,000 hours (that’s like 41 days straight!). Need something extra? We can tweak coatings for niche uses, like planes or offshore oil rigs.