Cross Recessed Screw

Send Inquiry

Cross Recessed Screw get special surface treatments to make them last longer. Zinc-nickel coatings have a strong anti-rust ability and are often used in ships or automobiles. The black oxide coating can reduce the gloss and enhance the grip when tightened, preventing the tool from slipping. Passivated stainless steel coatings can prevent rust without affecting electrical conductivity. Passivated stainless steel versions resist rust without messing with conductivity. Electro-polished finishes keep things clean for medical or food stuff. These treatments can protect the screws from environmental influences and make them better compatible with various materials such as aluminum-plastic and composite materials

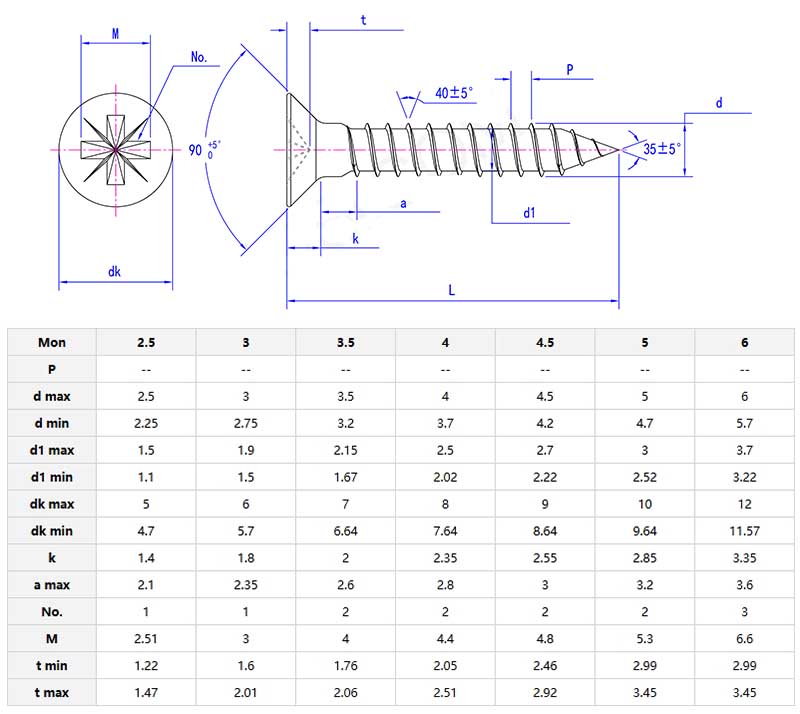

Product details and parameters

The size of the Cross Recessed Screw ranges from M2 to M12, and they are suitable for fine micro-operations as well as heavy-duty operations. Lengths range from 5mm up to 150mm, and the thread spacing is adjusted for different materials. For example, coarse threads are used for wood and fine threads for metal. Their head heights can be 2mm to 10mm, which helps them fit smoothly into all kinds of setups. You can get them in metric or imperial sizes, so they’re usable around the world. There are detailed technical drawings and CAD files ready for these screws, making it easier to include them in engineering designs.

FAQ

Q: Can Cross Recessed Screw replace traditional Phillips or slotted screws in existing applications?

A: This Screw is made to replace Phillip or slotted screw directly. The groove in the head moves more torque efficiently, so the screwdriver won’t slip and the screw won’t get damaged as easily. After you install them, the flat head sits flush with the surface, which is really important for industries where how things look matters, like furniture making or medical devices. We have charts to help you match these screws’ sizes (like M3 to M12) with your old systems, so you can use them without having to make expensive changes.