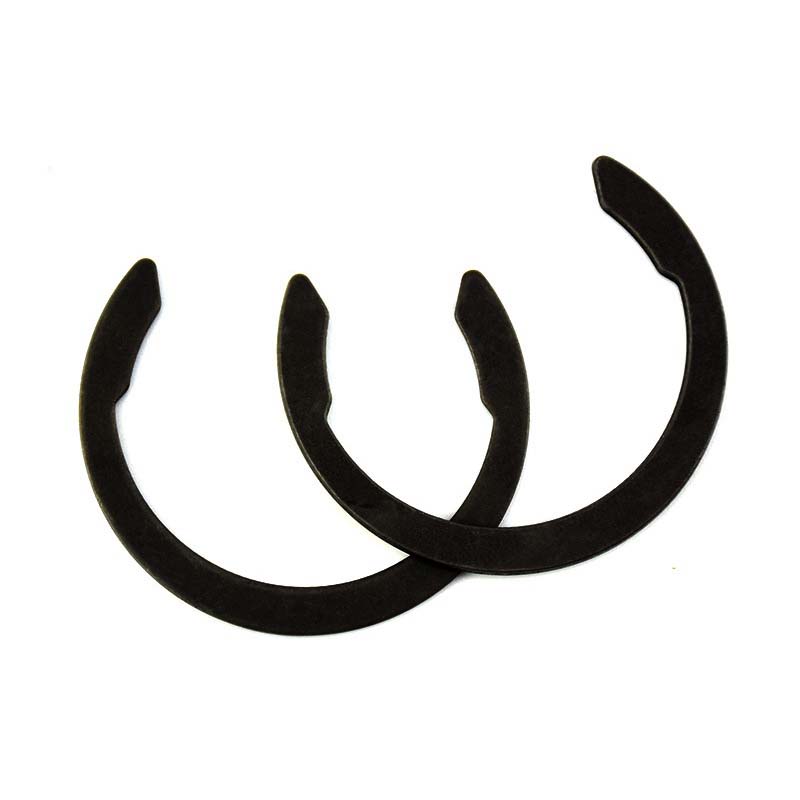

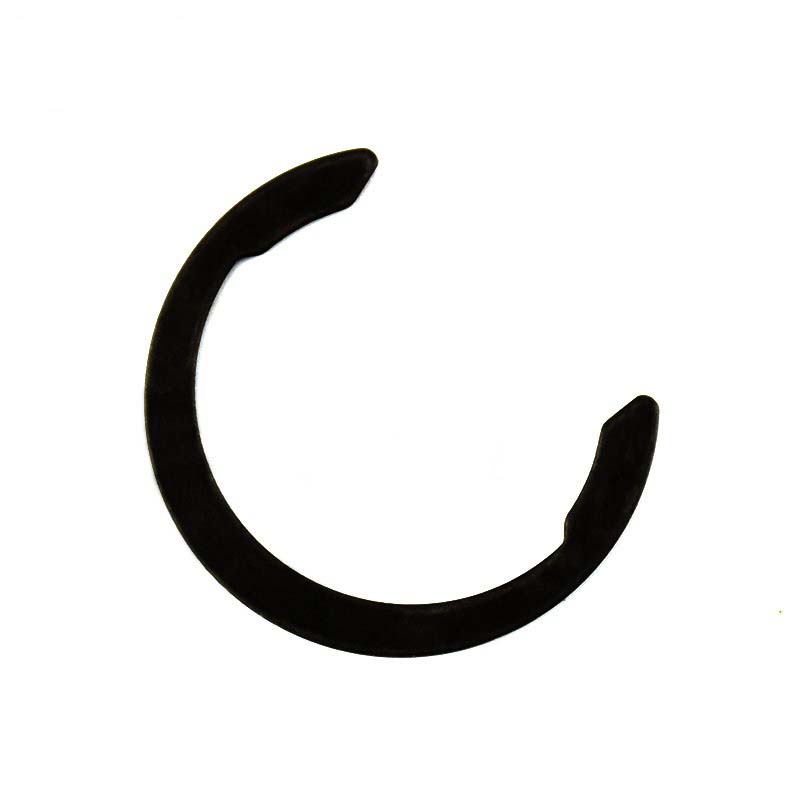

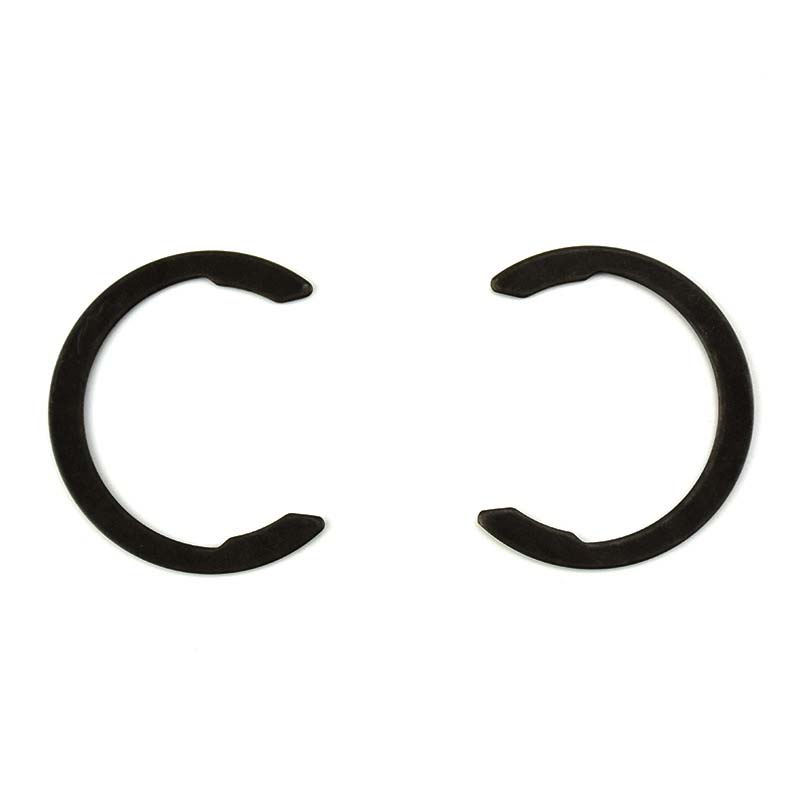

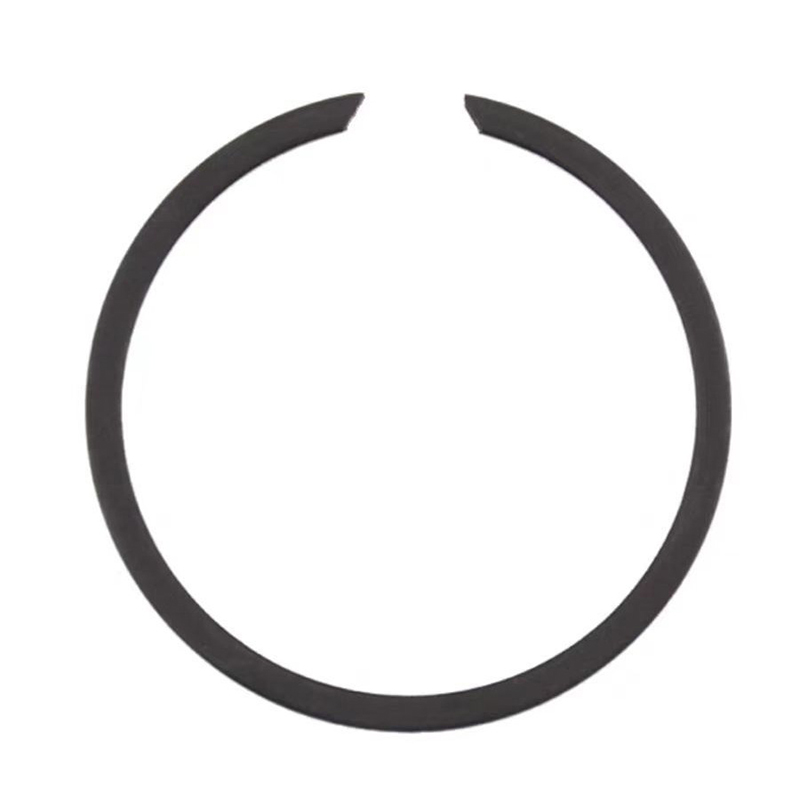

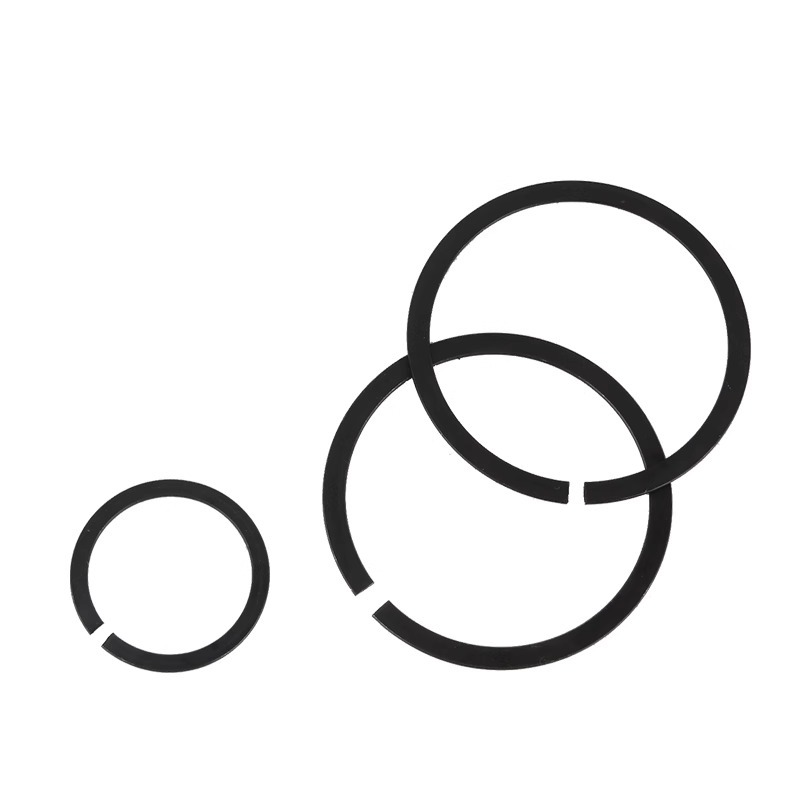

Metric Spring Retaining Ring

Send Inquiry

Metric spring retaining rings are usually made from high-carbon steel or stainless steel,such as ASTM A313. Carbon steel ones are stronger (like way stronger, up to 2,100 MPa), while stainless steel’s better at not rusting or corroding. If you heat-treat the alloys, they last longer and handle wear better. For jobs where you need stuff that doesn’t stick to magnets or can take crazy heat, they’ll use things like phosphor bronze or Inconel®. All the materials they use get put through a bunch of tests to check they meet ISO 8750-8752 specs.

Application

Metric spring retaining rings are really common in things like car transmissions, electric motors, and hydraulic systems. They’re used to hold rotor shafts in pumps, keep bearings in place in conveyor setups, and lock piston pins inside engines. In aerospace, you’ll find them in turbine parts and landing gear. They’re also handy in consumer electronics, where they help fix components in small devices. Engineers use spring retaining rings when they need parts to stay put reliably, especially in important systems where failures can’t happen.

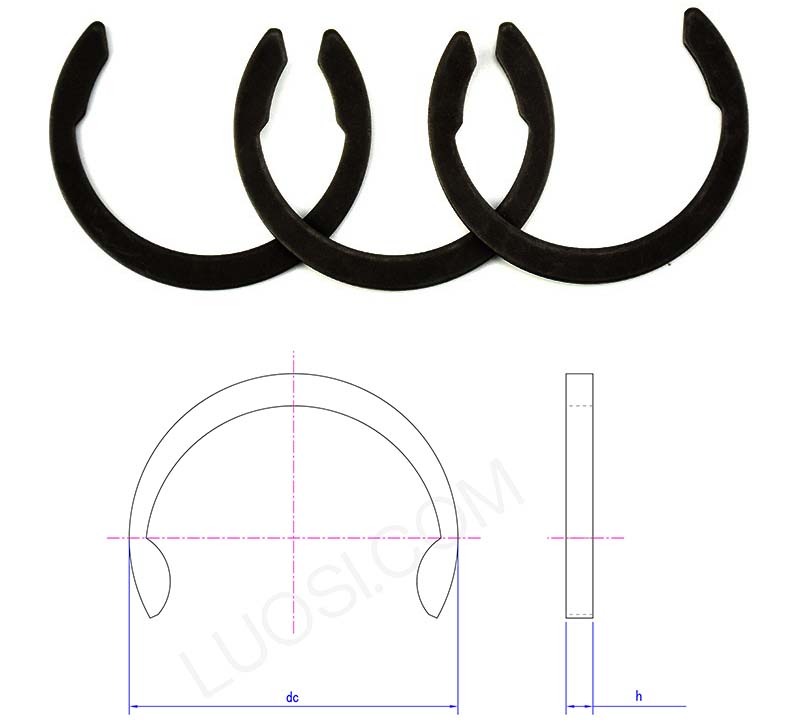

Size

Mon

Φ15

Φ16

Φ17

Φ18

Φ19

Φ20

Φ22

Φ23

Φ24

Φ25

Φ26

dc max

18

19

20

21

22

23

25

26.3

27.6

29.2

30

h min

0.97

0.97

0.97

1.17

1.17

1.17

1.17

1.17

1.17

1.17

1.17

h max

1.03

1.03

1.03

1.23

1.23

1.23

1.23

1.23

1.23

1.23

1.23

A:Choosing the right metric spring retaining ring is to match the groove diameter, shaft diameter or hole diameter and the load it needs to withstand. You need to carefully measure the width, depth and diameter of the mounting groove. Even small differences may cause them to not properly fix the parts.Choose the size according to your specific use case or project specifications, standard sizes such as DIN 471/472 or ANSI B27.1. If you require a custom installation, please let us know the installation temperature, whether the load is moving or stationary, and the environmental conditions (humid, dusty, etc.), and we will customize it to your needs.Spring retaining rings are manufactured for specific radial forces or axial forces, so you must check whether the load capacity of the retaining ring meets the needs of your project. We can provide technical support, one-stop service, and reduce the occurrence of premature fracture of retaining rings.