Large Mushroom Head Rivets

Send Inquiry

Large mushroom head rivets get different coatings depending on where they’ll be used. Here’s the deal:

Zinc coating (galvanizing): Stops rust, good for outdoors or wet spots.

Anodizing: For aluminum rivets – fights corrosion and adds color if you care about looks.

Acid baths (passivation): Cleans stainless steel rivets so they don’t react as much with chemicals.

Ceramic coatings: For super hot spots – acts like a heat shield.

Metal plating: Coat ’em with stuff like nickel or cadmium if they’ll get scraped a lot.

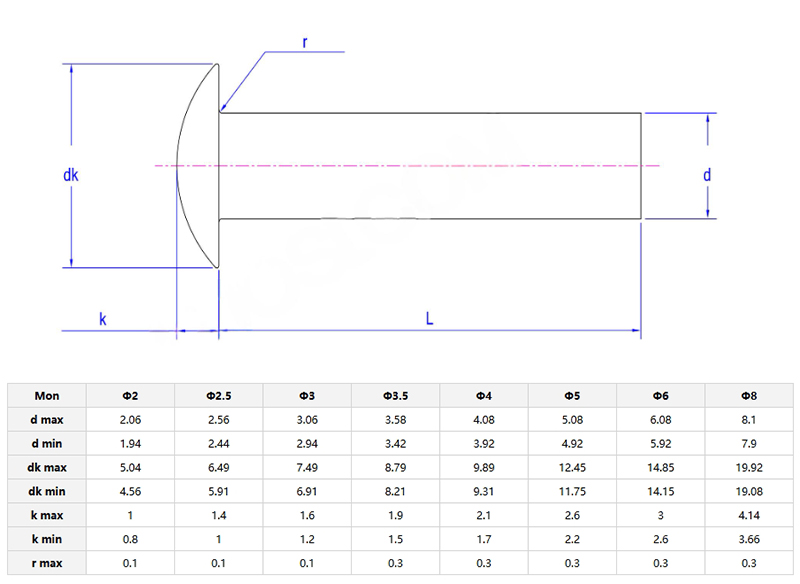

Product details and parameters

The parameters of large mushroom head rivets are numerous and diverse. The diameters range from 3 millimeters to 25 millimeters, and the lengths range from 6 millimeters to 100 millimeters. They have a wide range of applications and can meet the thickness requirements of different materials. The standard size follows the ISO 1051 and DIN 660 rules and is applicable to global engineering standards. If you need special sizes for specific projects, we can also provide customized services.

The ratio design of the rivet rod (straight part) and the rivet head is to prevent them from bending or deforming during installation. Different technical specifications will provide you with the best grip range for different uses, so whether you are dealing with thin metal sheets or thick structural plates, you can choose the appropriate size.

FAQ

Q: What tools are required to install large mushroom head rivets, and is specialized training needed?

A: Specialized training is necessary. If you want to install mushroom head rivets, you need to prepare a riveting gun or pneumatic tool that matches the size of the rivet. For small jobs, hand tools can do the job. However, large factories will use heavy equipment to speed up the construction process.

No fancy training needed, but stick to basics:

Drill holes exactly the right size (too big = loose rivet).

Line ’em up straight when popping the rivet in – keeps ’em from bending.

Don’t skip the gloves and safety glasses.