Industry Trusted Headed Studs

Send Inquiry

The Industry Trusted Headed Studs are used in the enclosures of electrical equipment to fix and secure the panels. They have a zinc-nickel coating on their surface, which helps prevent rusting. The price is very favorable, especially if you order more than 2000 pieces, you will save 9% of the cost. We ship by express delivery, which is cost-effective and takes 3 to 5 days to arrive. They are packed in plastic bags and placed in cardboard boxes. We will conduct an electrical conductivity test on them, and they have passed UL certification to ensure their safety for electrical use. We will also check the thickness of the coating before leaving the factory to ensure it meets the standards. These screws have reliable performance and help ensure the normal operation of the electrical system.

Product Benefits

Industry Trusted Headed Studs are commonly used in mining equipment as they maintain good performance under harsh conditions. They are made of heat-treated steel with a hardness ranging from HRC 30 to 35, which helps them resist wear. The prices are competitive and a 6% discount is offered when the order quantity reaches 1000 or more. We use heavy trucks for transportation - for large orders, this is an economical choice, usually taking 5 - 7 days. The bolts are packed in sturdy wooden boxes with waterproof functions. We also conduct impact tests (at least 50J) to check their strength, and they have passed ISO 14001 certification to ensure quality and durability. Due to their robustness, these bolts help extend the service life of mining equipment.

FAQ

Q: How are Industry Trusted Headed Studs typically installed, and do they require special equipment?

A: Sure. The Industry Trusted Headed Studs are usually installed using electric arc welding tools such as a bolt welding machine. These tools can firmly weld the bottom of the bolts to the metal surface (such as steel beams) in just a few seconds. You don't need to drill holes first, so the installation speed is very fast. When welding is not feasible, installation can also be completed by screwing the components into pre-drilled threaded holes with a regular wrench. We recommend using calibration tools to ensure the appropriate tightening degree and avoid over-tightening. We are happy to share the installation guide and help recommend suitable equipment so that you can install them firmly and achieve the best results for your project.

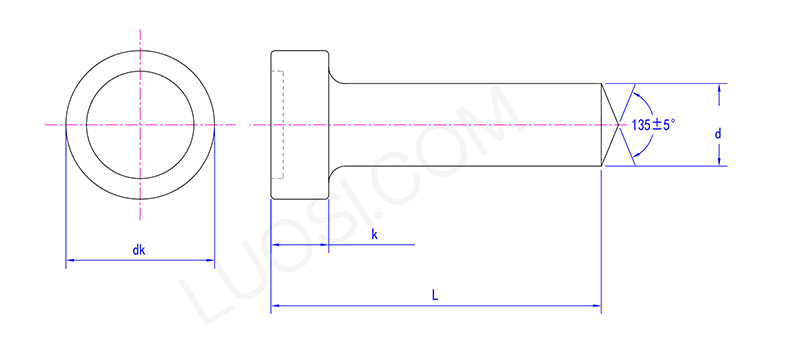

Product Parameters

| Mon |

Φ10 |

Φ13 |

Φ16 |

Φ19 |

Φ22 |

Φ25 |

| d max | 10 | 13 | 16 | 19 | 22 | 25 |

| d min | 9.6 | 12.6 | 15.6 | 18.6 | 21.6 | 24.6 |

| dk max | 19.3 | 25.3 | 32.3 | 32.3 | 35.3 | 40.3 |

| dk min | 18.7 | 24.7 | 31.7 | 31.7 | 34.7 | 39.7 |

| k max | 7.5 | 8.5 | 8.5 | 10.5 | 10.5 | 12.5 |

| k min | 6.5 | 7.5 | 7.5 | 9.5 | 9.5 | 11.5 |