Industry Standard Snap Rings

Send Inquiry

Industry Standard Snap Rings get used a lot in car transmissions, aerospace systems, and industrial machines—mainly because they’re good at keeping parts in place.

These things are important for holding bearings, gears, and other parts onto shafts or inside housings.This version merges the two sentences and uses verbs such as "simplify" and "ensure". The language is concise and fluent and is suitable for most technical documents.

In order to extend service life, high carbon steel and stainless steel are two materials that manufacturers commonly use in the production process. Industry-standard Snap rings are pretty flexible too—they can work in environments where things move fast or get really hot.

Product details

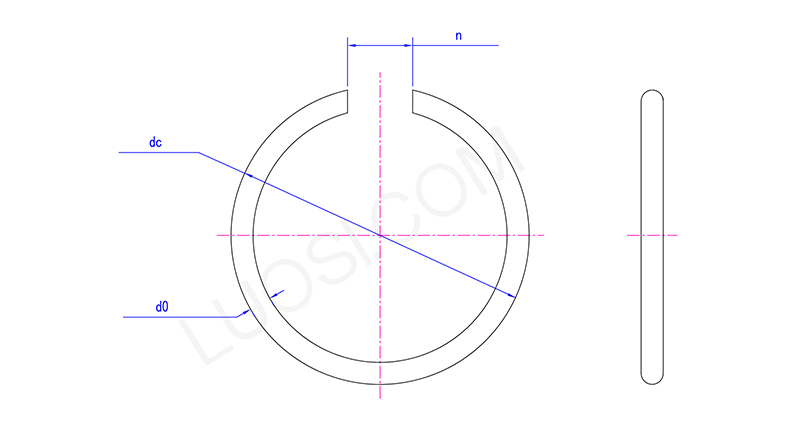

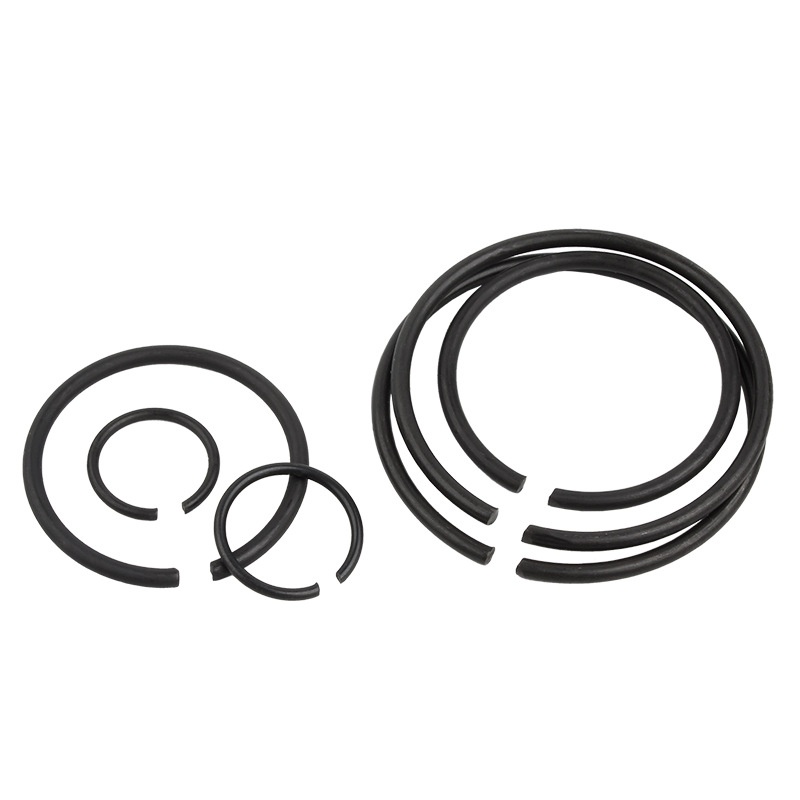

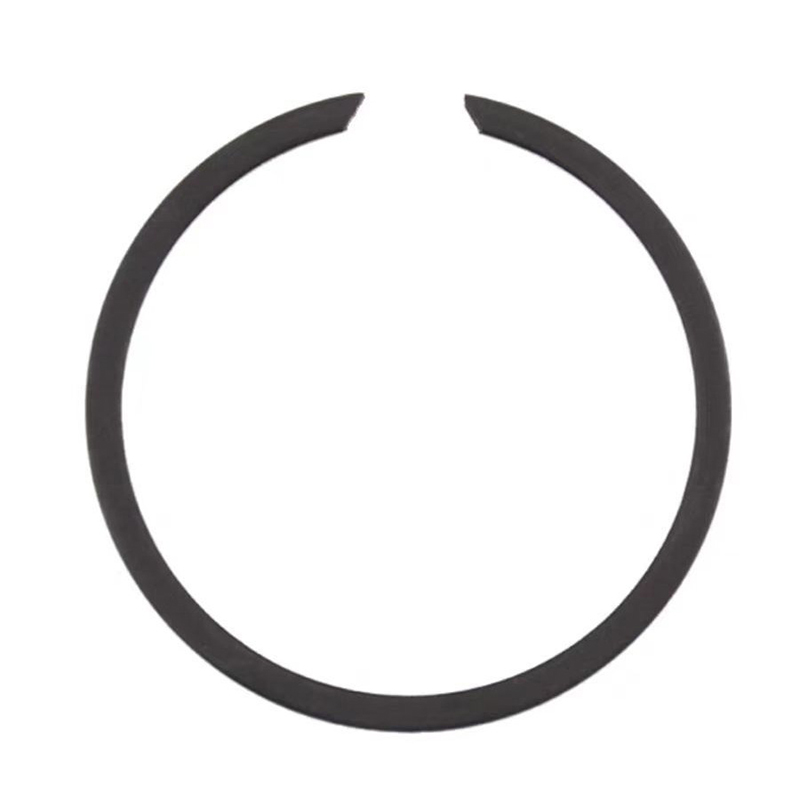

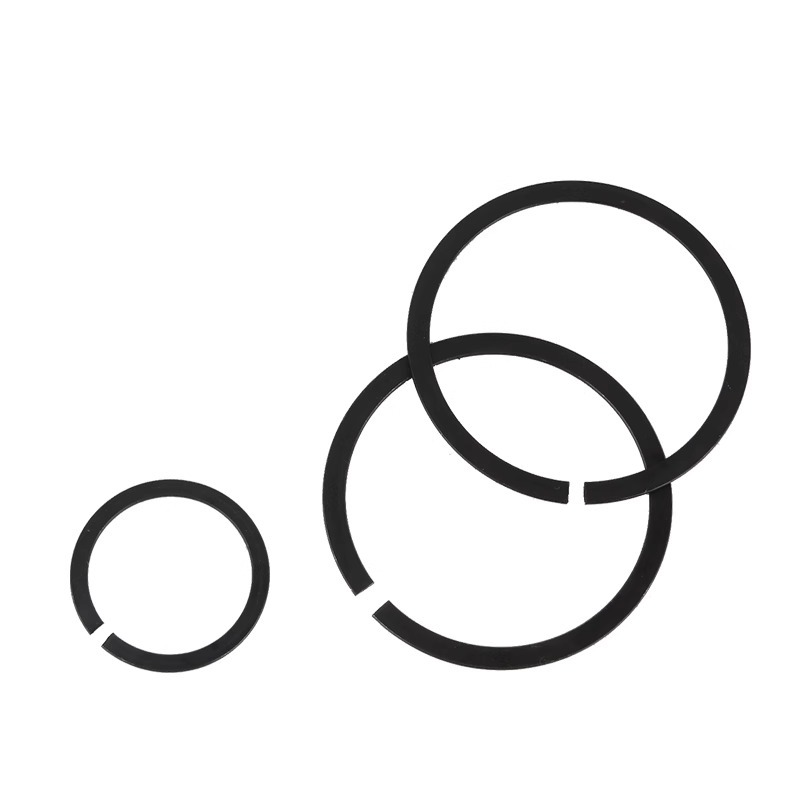

The Industry Standard Snap Rings is circular or semi-circular in appearance, with open ends. This design feature greatly improves the convenience of wearing and removing, and can more efficiently meet the wearing and taking off needs in daily use.

In order to achieve a tight fit with the target groove, their cross-section (the shape visible after cutting) has been specially designed and produced. Common shapes such as rectangular edges or rounded edges can effectively improve the fit.

They come in all kinds of sizes too: tiny ones for precision tools, and big ones for heavy-duty machines.

Their design is simple but works well—they don’t take up much space, but still give strong radial support (that’s support going out from the center, to keep parts from moving).

| Mon |

Φ15 |

Φ18 |

Φ20 |

Φ22 |

Φ24 |

Φ25 |

Φ26 |

Φ28 |

Φ30 |

Φ32 |

Φ55 |

| d0 max | 1.03 | 1.33 | 1.54 | 1.54 | 1.54 |

1.54 |

1.54 |

1.54 |

2.04 |

2.04 |

2.04 |

| d0 min | 0.97 | 1.27 | 1.46 | 1.46 |

1.46 |

1.46 |

1.46 |

1.46 |

1.96 | 1.96 | 1.96 |

| dc max | 17.6 | 21.5 | 23.7 | 25.8 | 28.2 | 29.2 | 30.4 | 32.4 | 35 | 37 | 40 |

| dc min | 17.1 | 20.5 | 22.7 | 24.8 | 27.2 | 28.2 | 29.4 | 31.4 | 34 | 36 | 39 |

| n max | 1.5 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| n min | 0.4 | 0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

Materials used

Our standard Industry Standard Snap Rings are crafted from high-carbon spring steel for superior strength and durability. For excellent corrosion resistance, we offer Industry Standard Snap Rings in stainless steel (e.g., 302/304), and other materials like phosphor bronze, ensuring longevity in harsh environments.