Flawlessly Matched Hexagonal Wrench

Send Inquiry

Quality is of vital importance to us. It is the foundation of our development and the basis of our commitment. The "perfect fit" feature of hexagonal wrenches is no accident - every product undergoes multiple rigorous inspections before officially leaving the factory, and the matching accuracy is ensured through full process control. To ensure that our wrenches meet established performance standards, we rigorously control dimensional accuracy using precision measuring tools. We also conduct simultaneous material hardness testing and torque performance testing to ensure comprehensive product quality assurance. Our quality control team carefully checks for any flaws in the processing, coating, or surface treatment processes. Conducting such comprehensive inspections before shipment means that each Flawlessly Matched Hexagonal Wrench you receive will work properly and have reliable performance.

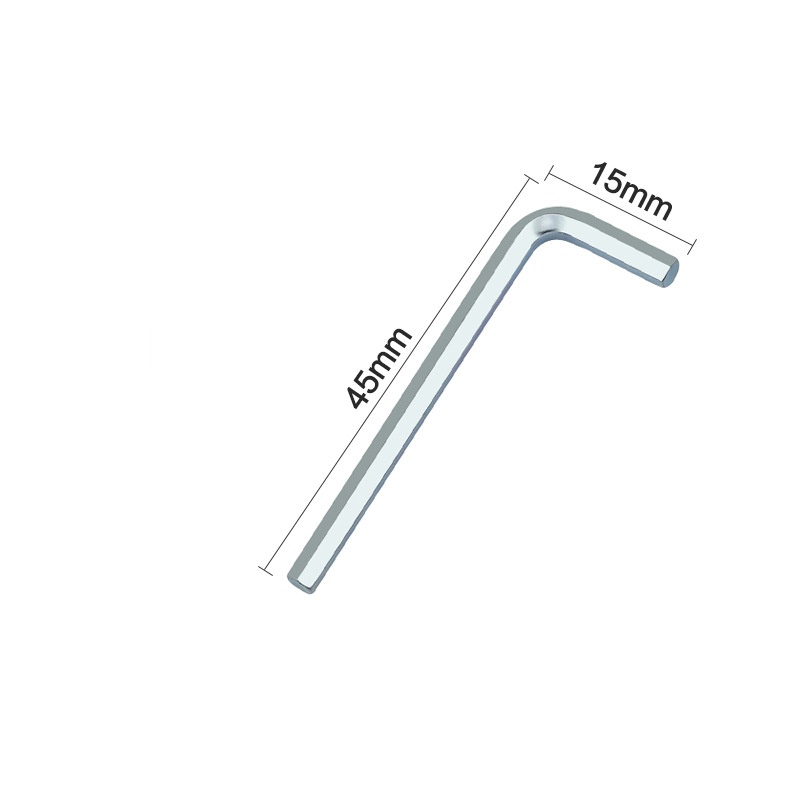

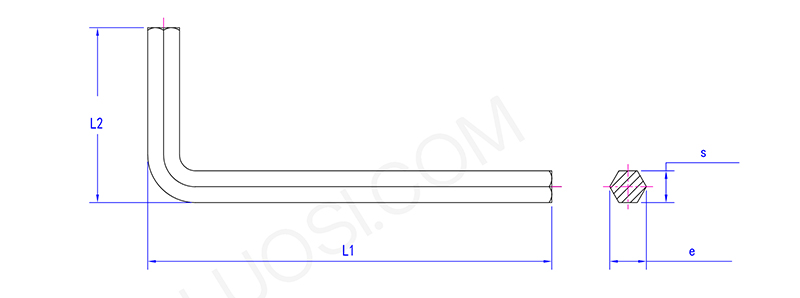

| Mon | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7 | 8 | 9 | 10 |

| s max | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7 | 8 | 9 | 10 |

| s min | 2.46 | 2.96 | 3.45 | 3.95 | 4.45 | 4.95 | 5.95 | 6.94 | 7.94 | 8.94 | 9.94 |

| e max | 2.82 | 3.39 | 3.96 | 4.53 | 5.1 | 5.67 | 6.81 | 7.94 | 9.09 | 10.23 | 11.37 |

| e min | 2.75 | 3.31 | 3.91 | 4.44 | 5.04 | 5.58 | 6.71 | 7.85 | 8.97 | 10.1 | 11.23 |

| L1 max | 58.5 | 66 | 69.5 | 74 | 80 | 85 | 96 | 102 | 108 | 114 | 122 |

| L1 min | 54.5 | 62 | 65.5 | 70 | 76 | 81 | 92 | 96 | 102 | 108 | 116 |

| L2 max | 20.5 | 23 | 25.5 | 29 | 30.5 | 33 | 38 | 41 | 44 | 47 | 50 |

| L2 min | 18.5 | 21 | 23.5 | 27 | 28.5 | 31 | 36 | 39 | 42 | 45 | 48 |

Product details

The products we produce and the final finished goods all have relevant certifications - they meet international quality and safety standards. Many of the Flawlessly Matched Hexagonal Wrench we manufacture are marked with symbols indicating that they follow strict standards, such as the ISO 9001 standard. This standard proves that our quality management system is outstanding. These certifications allow customers to learn from independent sources that the product is reliable, the material quality is excellent, and the manufacturing process also meets standards. When you choose our Flawlessly-Matched Hexagonal wrenches, you are purchasing a tool that has been professionally inspected and it also has real quality certification as support.

FAQ

Q: Can I use a Flawlessly Matched Hexagonal Wrench on damaged bolt sockets, and what’s the best approach if the socket is stripped?

A:For bolts with minor wear, you can use a Flawlessly Matched Hexagonal Wrench for tightening, but be careful - if the threaded sleeve is too loose, the wrench may slip and cause damage to the bolt or even hurt your hand.

If the damage is only minor, you can try using a slightly larger hex wrench (for example, for a worn 4.8mm sleeve, you can use a 5mm one), or use a ball-head type wrench - they sometimes provide a more secure fix for the component.

If the bolt is indeed damaged and loose, do not force it to tighten. First, you can try using specialized damaged bolt removal tools. If you must use a hex wrench, turn it slowly and evenly, and do not hit it with a hammer.

After the bolt is removed, it must be reinstalled in place according to the specifications; if the damaged sleeve continues to be used, the damage will be further aggravated, which may affect the accuracy of subsequent operations.