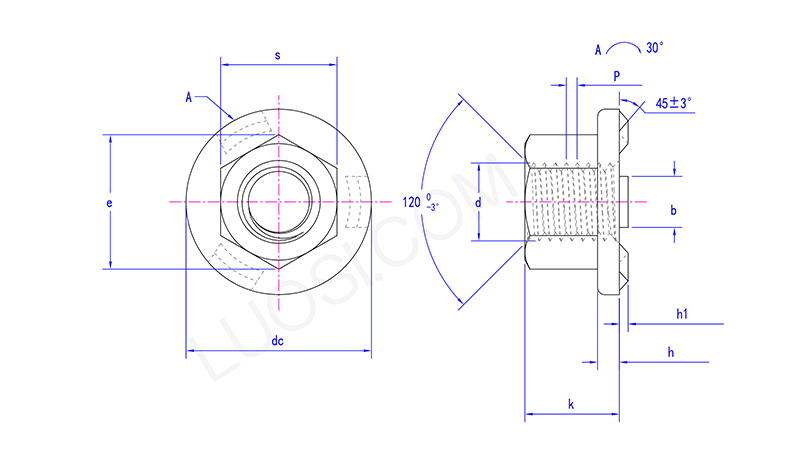

High Strength Weld Hexagon Nuts With Flange

Send Inquiry

What makes high strength weld hexagon nuts with flange different is that they’re made to be welded. Usually, there’s a little raised part for welding,a small ring or bump,on the bottom of the flange, or maybe a specially prepared angled edge. This raised part melts first when you weld (either arc or projection welding), which helps create a strong, even, deep bond between the flange base and the piece you’re working on. That way, it stays attached permanently.

Specific parameters:

Parameters such as thread half angle, pitch deviation and pitch diameter tolerance of metric threads follow standards such as ISO 965-1, GB/T 197 or DIN 14. This means that they can be replaced if necessary and nuts can be screwed onto them precisely.Parameters such as thread half angle, pitch deviation and pitch diameter tolerance of metric threads follow standards such as ISO 965-1, GB/T 197 or DIN 14. They can be replaced if necessary and nuts can be screwed onto them precisely.

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| h1 max | 0.9 | 0.9 | 1.1 | 1.3 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.7 | 0.7 | 0.9 | 1.1 | 1.1 | 1.1 | 1.1 |

| dc max | 15.5 | 18.5 | 22.5 | 26.5 | 30.5 | 33.5 | 36.5 |

| dc min | 14.5 | 17.5 | 21.5 | 25.5 | 29.5 | 32.5 | 35.5 |

| e min | 8.2 | 10.6 | 13.6 | 16.9 | 19.4 | 22.4 | 25 |

| h max | 1.95 | 2.25 | 2.75 | 3.25 | 3.25 | 4.25 | 4.25 |

| h min | 1.45 | 1.75 | 2.25 | 2.75 | 2.75 | 3.75 | 3.75 |

| b max | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 8.1 | 8.1 |

| b min | 3.9 | 4.9 | 5.9 | 6.9 | 7.9 | 7.9 | 7.9 |

| k min | 4.7 | 6.64 | 9.64 | 12.57 | 14.57 | 16.16 | 18.66 |

| k max | 5 | 7 | 10 | 13 | 15 | 17 | 19.5 |

| s max | 8 | 10 | 13 | 16 | 18 | 21 | 24 |

| s min | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 |

Effects of Directness and Thickness on Performance:

The size of the flange on these weld hexagon nuts affects how the load spreads, how well they handle vibration, and how strong the weld is. A bigger or thicker flange means more stability and more contact with the surface. Picking the right flange size for these nuts is important for how well the joint works.