High Strength Hexagon Domed Cap Nuts

Send Inquiry

High strength hexagon domed cap nuts have a hex socket inside (so you use an Allen key) to install and tighten them. Sometimes, there’s a hex-shaped base on the bottom under the dome for this too. This design lets you apply high torque, which helps get the clamping force you need,good thing they’re strong enough for that.

They aren’t super secure by default, but that smooth dome shape does keep people from tampering with them a bit more than regular nuts. Regular wrenches can’t get a good grip on them easily. If you need more security, you can sometimes add special drive types or unique patterns to their design.

Application

High strength hexagon domed cap nuts get used a lot in places that need both good mechanical performance and a nice, finished look,or a cover that protects things. Common areas include cars,like suspension parts, engines, body panels; aerospace, such as interiors and panels; heavy machinery, like covers and frames; construction equipment; marine hardware; high-end furniture assembly; and architectural metal work.

Anywhere you need them to resist vibration, hold heavy loads, avoid sharp bits that could cause issues, and resist rust,plus they look nice,these high strength domed cap nuts work really well as fasteners.

What is the recommended installation torque when used with grade 8 bolts?

Getting the torque right is really important for them to work their best. Take our high strength hexagon domed cap nuts used with Grade 8 bolts,like the ½"-13 UNC size, for example. The suggested dry torque is 85-90 ft-lbs (115-122 Nm). If you use lube, turn that down by 15-20%.

Always check the specific engineering standards for your use case, though. The exact torque depends on the bolt size, whether there’s lube, and how the joint is designed.

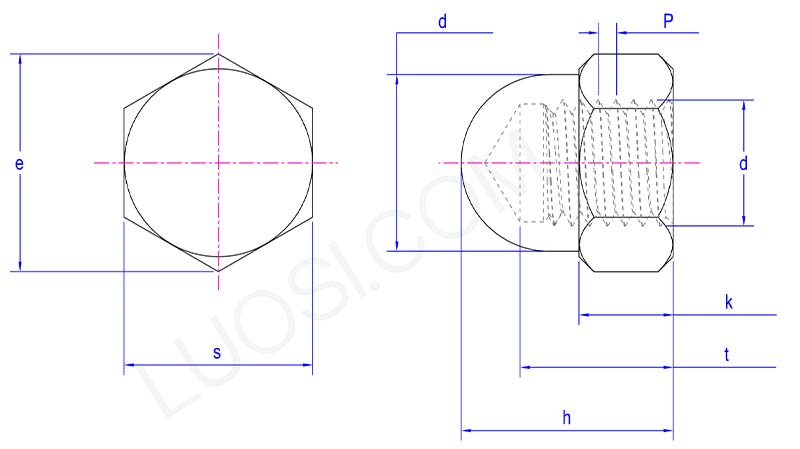

Mon

M12

M14

M16

M18

M20

M22

M24

P

1.25|1.5|1.75

1.5|2

1.5|2

1.5|2|2.5

1.5|2|2.5

1.5|2|2.5

2|3

dk max

17

20

23

26

28

31

34

e min

19.85

22.78

26.17

29.56

32.95

35.03

39.55

h max

22

25

28

32

34

39

42

h min

21.16

24.16

27.16

31

33

38

41

k max

10

11

13

15

16

18

19

k min

9.64

10.3

12.3

14.3

14.9

16.9

17.7

s max

18

21

24

27

30

32

36

s min

17.57

20.16

23.16

26.16

29.16

31

35

t min

15.65

17.65

20.58

24.58

25.58

28.58

30.5

t max

16.35

18.35

21.42

25.42

26.42

29.42

31.5