High Precision Weld Hexagon Nuts With Flange

Send Inquiry

To keep them from rusting, high precision Weld hexagon nuts with flange are usually electroplated with zinc. This zinc coating often clear, yellow, or black chromated,acts like a protective layer that takes the damage instead, making them hold up better against the environment. Zinc-plated ones offer decent rust protection and don’t cost too much, which works for a lot of industrial settings.

Rust prevention:

For better rust protection in tough places,like marine areas, around chemicals, or outdoor structures high precision Weld hexagon nuts with flange get hot-dip galvanized.This process coats the entire nut, including the critical flange base and welded areas, with a dense zinc-iron coating that lasts even in high-humidity, salty environments.

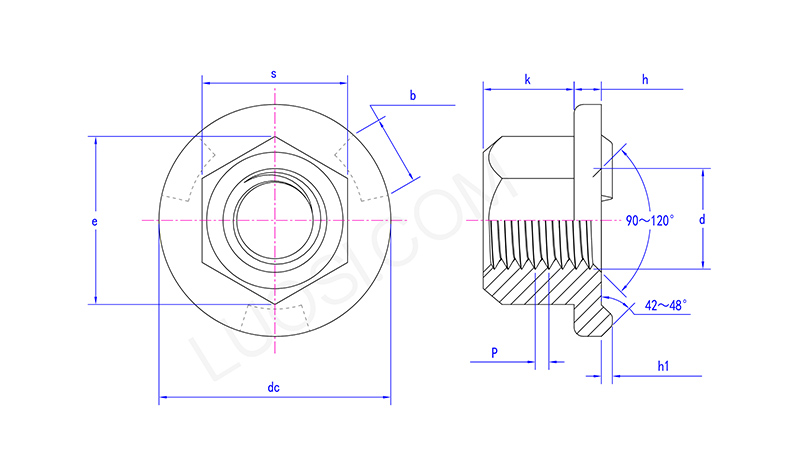

| Mon | M8 | M10 | M12 | M14 |

| P | 1.25 | 1.5 | 1.75 | 2 |

| h1 max | 1.1 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.9 | 1.1 | 1.1 | 1.1 |

| dc max | 22.5 | 26.5 | 30.5 | 33.5 |

| dc min | 21.5 | 25.5 | 29.5 | 32.5 |

| e min | 13.6 | 16.9 | 19.4 | 22.4 |

| h max | 2.75 | 3.25 | 3.25 | 4.25 |

| h min | 2.25 | 2.75 | 2.75 | 3.75 |

| b max | 6.1 | 7.1 | 8.1 | 8.1 |

| b min | 5.9 | 6.9 | 7.9 | 7.9 |

| k min | 9.64 | 12.57 | 14.57 | 16.16 |

| k max | 10 | 13 | 15 | 17 |

| s max | 13 | 16 | 18 | 21 |

| s min | 12.73 | 15.73 | 17.73 | 20.67 |

Standards and sizes:

High precision Weld hexagon nuts with flange usually come in metric (ISO) and imperial (UNC/UNF) thread sizes. Common sizes go from M4/M5 up to M24, or 1/4" up to 1". Exactly what’s available depends on who makes them and what material grade you need.