Cost Effective Welding Flange Nut

Send Inquiry

In applications that carry heavy loads, Cost Effective Welding flange nuts are known to perform well. Because the nut is welded on and made from strong materials, it can handle a lot of weight. You’ll find these nuts used in important structures like bridges or large industrial machines, where they connect essential parts. The flange helps spread the pressure evenly and keeps the joint tight even under strain, which is key to keeping everything safe and working as it should.

Product details

The threads on a Cost Effective Welding flange nut are made to match standard industry sizes, so they fit common bolts and screws without issues. Whether it’s metric or unified threading, the nut screws on smoothly and stays tight. Good threading also helps the nut resist shaking loose from vibration, which makes it a reliable choice in moving or high-vibration situations.

Q: Is the surface finish on the Cost Effective Welding flange nut important for welding?

A:Yes, a clean, uniform surface is critical. While our zinc-plated Cost-Effective Welding flange nut offers protection, the plating must be removed from the welding contact area to ensure a pure, strong metallurgical bond and prevent weld contamination.

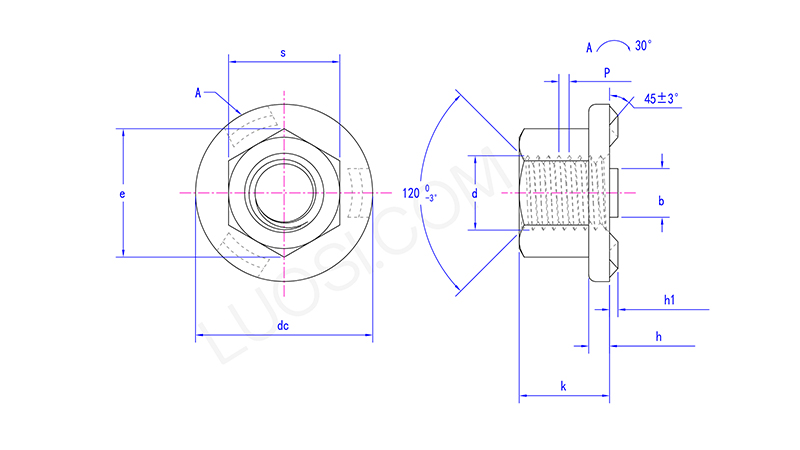

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| h1 max | 0.9 | 0.9 | 1.1 | 1.3 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.7 | 0.7 | 0.9 | 1.1 | 1.1 | 1.1 | 1.1 |

| dc max | 15.5 | 18.5 | 22.5 | 26.5 | 30.5 | 33.5 | 36.5 |

| dc min | 14.5 | 17.5 | 21.5 | 25.5 | 29.5 | 32.5 | 35.5 |

| e min | 8.2 | 10.6 | 13.6 | 16.9 | 19.4 | 22.4 | 25 |

| h max | 1.95 | 2.25 | 2.75 | 3.25 | 3.25 | 4.25 | 4.25 |

| h min | 1.45 | 1.75 | 2.25 | 2.75 | 2.75 | 3.75 | 3.75 |

| b max | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 8.1 | 8.1 |

| b min |

3.9 |

4.9 |

5.9 |

6.9 |

7.9 |

7.9 |

7.9 |

| k min | 4.7 | 6.64 | 9.64 | 12.57 | 14.57 | 16.16 | 18.66 |

| k max | 5 | 7 | 10 | 13 | 15 | 17 | 19.5 |

| s max | 8 | 10 | 13 | 16 | 18 | 21 | 24 |

| s min | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 |