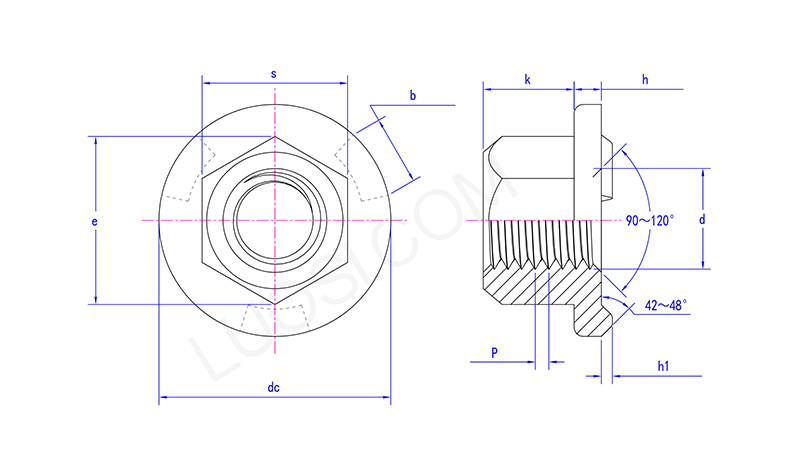

High Precision Hex Weld Lock Nuts With Flange

Send Inquiry

Because these high precision hex weld lock nuts with flange have a wide base and are welded on permanently, they don’t loosen up easily from vibration. The weld keeps them from spinning, and the flange helps prevent settling and spreads out moving loads well. That’s why they’re better than regular nuts for machines that vibrate or in transport uses.

Regular maintenance:

Once these high precision hex weld lock nuts with flange are welded on, they don’t need much upkeep. The most important thing is to regularly inspect the coating on the welds and threads. Over time, check for rust or cracks, porosity, and other defects. It's best to regularly inspect the welds and surrounding areas. If any problems are found, gently sand them with fine sandpaper to remove loose rust.

| Mon | M8 | M10 | M12 | M14 |

| P | 1.25 | 1.5 | 1.75 | 2 |

| h1 max | 1.1 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.9 | 1.1 | 1.1 | 1.1 |

| dc max | 22.5 | 26.5 | 30.5 | 33.5 |

| dc min | 21.5 | 25.5 | 29.5 | 32.5 |

| e min | 13.6 | 16.9 | 19.4 | 22.4 |

| h max | 2.75 | 3.25 | 3.25 | 4.25 |

| h min | 2.25 | 2.75 | 2.75 | 2.75 |

| b max |

6.1 |

7.1 | 8.1 | 8.1 |

| b min | 5.9 | 6.9 | 7.9 | 7.9 |

| k min | 9.64 | 12.57 | 14.57 | 16.16 |

| k max | 10 | 13 | 15 | 17 |

| s max | 13 | 16 | 18 | 21 |

| s min | 12.73 | 15.73 | 17.73 | 20.67 |

Test report:

Good suppliers can give you high precision hex weld lock nuts with flange that come with full material tracking, test reports on their chemical and physical properties (MTR), and certifications like ISO 9001, DIN, or standards specific to certain industries,like automotive. When you order these nuts, ask about the certification needs beforehand.